I-TiAlSi Sputtering Target High Purity Thin Film Pvd Coating Ngokwezifiso

I-Titanium Aluminium Silicon

Incazelo yethagethi ye-Titanium Aluminium Silicon Sputtering

Ithagethi ye-Titanium Aluminium Silicon sputtering yenziwa ngensimbi yamandla.

I-Titanium Aluminium Silicon alloy isetshenziswa ngokujwayelekile ekwenzeni injini yezimoto. Inokufaneleka okuhle kakhulu kwezinga lokushisa eliphezulu nokumelana nokugqoka. Ukusetshenziswa kwe-Ti-Al-Si alloy kungandisa kakhulu impilo yezingxenye zenjini cishe ngama-35%. Ngokuqondene nokusetshenziswa kwayo esithuthuthu nasesondoni lezimoto, ikhombisa ukukwazi ukusebenza kangcono, ukusebenziseka kalula, ukumelana nokukhathala kanye nokuqina komthelela kune-A356 Aluminium.

Ingxubevange ye-aluminium eqina ngokushesha ingatholwa ngenqubo yokuqinisa esheshayo ebizwa ngokuthi "i-melt spinning", ekhiqiza izakhiwo eziphakeme uma iqhathaniswa ne-alloy evamile ye-aluminium, kanye ne-microstructure ehlanjululwe kahle kanye nokuguquguquka okwengeziwe kwe-alloying. Kuyinto engaba khona embonini yezindiza ukuze ithathe indawo ye-Titanium base alloy esetshenziswe ku-150-300 ℃.

Phakathi nenqubo yokubeka imigomo ye-TiAlSi, i-TiAlSi/TiAlSiN ingakhiwa ngayodwana njengezendlalelo eziningi zekristalu yekhwalithi ephezulu enezakhiwo eziningi ze-cubic. Lezi zimbotshana ezinezendlalelo eziningi zenze lezi zinto zokunamathisela eziqinile ukuze kwandiswe impilo yonke yamathuluzi asetshenziselwa izindawo ezinokhahlo.

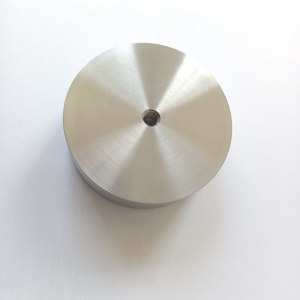

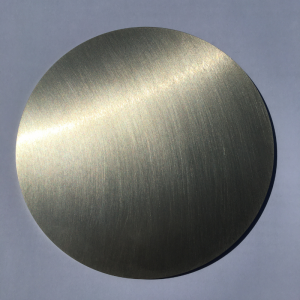

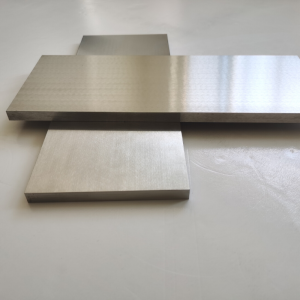

I-Titanium Aluminium Silicon Sputtering Target Packaging

Ithagethi yethu ye-Titanium Aluminium Silicon sputter imakwe ngokucacile futhi ifakwe ilebula ngaphandle ukuze kuqinisekiswe ukuhlonza okuphumelelayo nokulawula ikhwalithi. Kuqikelelwa kakhulu ukugwema noma yimuphi umonakalo ongase udalwe ngesikhathi sokugcinwa noma ukuthutha.

Thola Othintana Naye

Amathagethi e-RSM's Titanium Aluminium Silicon sputtering anobumsulwa obuphezulu kanye nomfaniswano. Atholakala ngezindlela ezihlukahlukene, ama-purities, amasayizi, namanani. Sisebenza ngokukhethekile ekukhiqizeni izinto zokumboza zefilimu ezihlanzekile nezincane ezisebenza kahle kakhulu kanye nokuminyana okuphezulu kakhulu okungaba khona kanye nosayizi omncane wokusanhlamvu ophakathi okungenzeka ukuthi usetshenziswe ekuhlanganiseni isikhunta, ukuhlobisa, izingxenye zemoto, ingilazi engu-E ephansi, isekethe ehlanganisiwe ye-semi-conductor, ifilimu elincanyana. ukumelana, isibonisi sezithombe, i-aerospace, ukurekhoda kazibuthe, isikrini sokuthinta, ibhethri yelanga lefilimu elincanyana kanye nezinye izinhlelo zokusebenza zokubeka umhwamuko (PVD). Sicela usithumelele uphenyo mayelana nentengo yamanje ekuhlosweni kwe-sputtering nezinye izinto zokubeka ezingabaliwe.