Ngaphambili, amakhasimende amaningi abuze ozakwabo boMnyango Wezobuchwepheshe we-RSM mayelana ne-titanium alloy. Manje, ngingathanda ukukufingqa amaphuzu alandelayo mayelana nokuthi insimbi ye-titanium alloy yenziwe ngani. Ngethemba ukuthi bangakusiza.

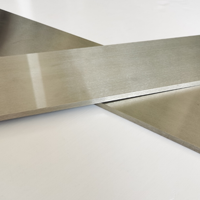

I-Titanium alloy iyingxubevange eyenziwe nge-titanium nezinye izakhi.

I-Titanium iyikristalu e-homogeneous heterogeneous, enephuzu lokuncibilika elingu-1720 ℃. Uma izinga lokushisa lingaphansi kuka-882 ℃, linokwakheka kwe-lattice ene-hexagonal esondelene, ebizwa ngokuthi i-α Titanium; Inokwakheka kwe-cubic egxile emzimbeni ngaphezu kuka-882 ℃, ebizwa nge-β Titanium. Kusetshenziswa izici ezihlukene zezakhiwo ezimbili ezingenhla ze-titanium, izakhi ezifanele ze-alloy zengezwa ukuze zishintshe kancane kancane izinga lokushisa lokuguqulwa kwesigaba kanye nokuqukethwe kwesigaba ukuze kutholwe ama-alloys e-titanium anezakhiwo ezahlukene. Ezingeni lokushisa lasekamelweni, amaalloyi e-titanium anezinhlobo ezintathu zezakhiwo ze-matrix, futhi ama-titanium alloy nawo ahlukaniswe abe izigaba ezintathu ezilandelayo: α Ingxubevange( α+β) Ingxubevange kanye ne-β Alloy. E-China, kukhonjiswa yi-TA, TC kanye ne-TB ngokulandelana.

α titanium ingxubevange

I-alloy yesigaba esisodwa esakhiwe ngesisombululo esiqinile sesigaba i-α Isigaba, isakhiwo esizinzile, ukumelana nokugqoka okuphezulu kune-titanium ehlanzekile, ukumelana ne-oxidation eqinile. Ngaphansi kwezinga lokushisa elingu-500 ℃~600 ℃, isawagcina amandla ayo kanye nokumelana nokukhasa, kodwa ayikwazi ukuqiniswa ukwelashwa kokushisa, futhi amandla ayo okushisa kwegumbi awaphezulu.

β titanium ingxubevange

Kungu-β Ingxube yesigaba esisodwa esakhiwe ngesisombululo esiqinile sesigaba sinamandla aphezulu ngaphandle kokwelashwa kokushisa. Ngemuva kokucisha nokuguga, i-alloy iqiniswa ngokwengeziwe, futhi amandla okushisa ekamelweni angafinyelela ku-1372 ~ 1666 MPa; Kodwa-ke, ukuzinza kwe-thermal kubi futhi akufanelekile ukusetshenziswa emazingeni okushisa aphezulu.

α+β titanium ingxubevange

I-alloy yesigaba esikabili enezici ezinhle ezihlanganisayo, ukusimama okuhle kwesakhiwo, ukuqina okuhle, ipulasitiki kanye nezakhiwo zokuguquguquka kwezinga lokushisa eliphezulu. Ingasetshenziselwa ukucubungula ingcindezi eshisayo, ukucisha nokuguga ukuqinisa i-alloy. Amandla ngemva kokwelashwa okushisa acishe abe ngu-50% ~ 100% ngaphezu kwalokho ngemva kokuhushula; Amandla okushisa aphezulu, angasebenza ku-400 ℃~500 ℃ isikhathi eside, futhi ukuzinza kwawo okushisayo kungaphansi kwe-alpha Titanium alloy.

Phakathi kwezingxube ezintathu ze-titanium α Titanium alloys kanye ne-α+β Titanium alloy; Ingxubevange ye-α ye-Titanium inokusebenziseka okuhle kakhulu, i-α+ P Titanium alloy ithatha indawo yesibili, i-β Titanium alloy ayilungile. α Ikhodi ye-titanium alloy ithi TA, β Ikhodi ye-titanium alloy yi-TB, α+β Ikhodi ye-titanium alloy ithi TC.

Ama-alloys e-Titanium angahlukaniswa abe ama-alloys angashisi, ama-alloys aphezulu, ama-alloys angagqwali (i-titanium molybdenum, i-titanium palladium alloys, njll.), ama-alloys asezingeni eliphansi kanye nama-alloys akhethekile asebenzayo (izinto zokugcina i-titanium iron hydrogen kanye ne-titanium nickel memory alloys ) ngokwezicelo zabo.

Ukwelashwa kokushisa: i-titanium alloy ingathola ukubunjwa kwesigaba esihlukile kanye nesakhiwo ngokulungisa inqubo yokwelapha ukushisa. Ngokuvamile kunenkolelo yokuthi i-fine equiaxed microstructure ine-plasticity enhle, ukuzinza okushisayo namandla okukhathala; Isakhiwo se-acicular sinamandla aphezulu okuphuka, amandla okukhasa kanye nokuqina kokuphuka; Izicubu ezixubile ezilinganayo ne-acicular zinemisebenzi engcono ebanzi

Isikhathi sokuthumela: Oct-26-2022