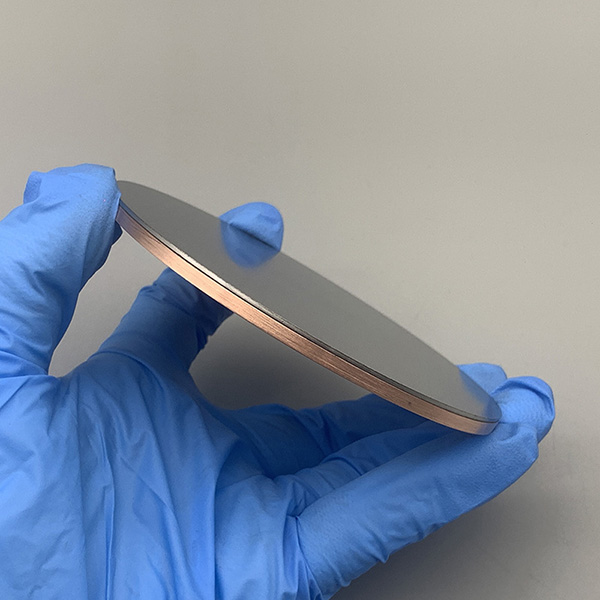

Ukwethulwa okuyisisekelo kwethagethi ye-Iron chromium aluminium alloy :

I-iron chromium aluminium alloy target iwuhlobo lwe-alloy material eyakhiwe ngensimbi, i-chromium ne-aluminium. Phakathi kwazo, insimbi iyinsimbi eyisisekelo, i-chromium iyisici sokuqinisa ingxubevange, futhi i-aluminium iyindima yokuzinzisa. Ngenxa yamandla ayo aphezulu, ukuzinza okuphezulu kwezinga lokushisa, ukumelana nokugqwala nezinye izinto ezinhle kakhulu.

Izici ze-iron chromium aluminium alloy:

1.Amandla aphezulu: i-ferrochrome aluminium alloy inamandla amakhulu, amandla ayo aphezulu kunensimbi evamile, angahlangabezana nezidingo ezihlukahlukene zamandla aphezulu wezidingo zobunjiniyela.

2. Ukuqina kwezinga lokushisa eliphezulu: ingxubevange ye-aluminium ye-ferrochrome isenamandla amahle nokuzinza emazingeni okushisa aphezulu, futhi ingasetshenziselwa imishini namathuluzi ezindaweni zokushisa okuphezulu.

3. Ukumelana nokugqwala: Ngemva kokuphathwa kwe-aluminium alloy ye-ferrochrome, kungavimbela ukukhathala, ukuqhekeka nezinye izinkinga ezibangelwa ukugqwala, okulungele i-Marine, amakhemikhali nezinye izindawo.

4. Imishini emihle: I-Fe-Cr aluminium alloy inomshini omuhle futhi ingasetshenziswa ekubumbeni, ekubumbeni, ekukhishweni kwepulasitiki nezinye izinqubo.

Ukusetshenziswa kwe-iron chromium aluminium alloy:

Ngenxa yezakhiwo zayo ezinhle kakhulu zomzimba namakhemikhali, ingxubevange ye-FeCrAl isetshenziswa kakhulu kwezokundiza, i-aerospace, izimoto, amakhemikhali neminye imikhakha. Ububanzi bayo bokusebenza buhlanganisa izici ezimbalwa:

1. Izinkambu zezindiza kanye ne-aerospace: Ngenxa yamandla ayo aphezulu, ukuzinza okuphezulu kwezinga lokushisa, ukumelana nokugqwala nezinye izici, i-ferrochrome aluminium alloy isetshenziswa kabanzi emkhakheni we-aerospace wokukhiqiza nokugcinwa.

2. Inkambu yezimoto: I-Ferrochrome aluminium alloy isetshenziswa kabanzi ekwenzeni izinjini zezimoto, amabhuleki, amagobolondo, chassis nezinye izingxenye.

Imboni ye-3.Chemical: i-aluminium alloy ye-ferrochrome nayo inokumelana nokugqwala okuhle kakhulu futhi ingamelana ne-asidi, i-alkali nokunye ukugqwala, ngakho-ke isetshenziswa kabanzi ekwenzeni imishini yamakhemikhali.

Kungani i-sputtering target idinga ukubopha indiza yangemuva?

I-1.Ukushisa kokushisa: Phakathi nenqubo yokufafaza, okuhlosiwe kuzothatha inani elikhulu lamandla, okuholela ekwandeni kwezinga lokushisa. Ukubophezela indiza yangemuva ene-thermal conductivity ephezulu (njenge-backplane yethusi) ingaqhuba ngempumelelo ukushisa okukhiqizwa ithagethi, igcine ukuzinza kwethagethi kanye nokufafaza okufanayo.

2.Ukwesekwa kwemishini: Okuqondiwe kungaphansi komthelela womzimba oqhubekayo ngesikhathi sokusetshenziswa, futhi ukubophezela endizeni engemuva eqinile kunikeza ukusekelwa okwanele komshini ukuze kuvinjelwe okuqondiwe ekuqhekekeni noma ekuwohlokeni.

3.Impilo yesevisi ethuthukisiwe: Ngokukhipha ukushisa okusebenzayo kanye nokusekelwa kwemishini kwendiza engemuva, ukulahlekelwa nokuguqulwa kwethagethi kungancishiswa, ngaleyo ndlela kwelule impilo yesevisi yalokho okuhlosiwe.

4.Ikhono lokufafaza elithuthukisiwe: Ibhanoyi elingemuva lingasiza okuqondiwe ukuthi kutholwe amandla omthombo wamandla afafazayo ngokulinganayo, kuzuze ukubekwa kwefilimu okusebenza kahle kakhulu nokufana okufanayo.

indlela yokubopha indiza yangemuva?

1. Pretreat the target and backplane surface ngaphambi kokubopha

2. Beka i-target kanye ne-backplane phezu kwetafula lokunamathisela bese ushisa kuze kufike ezingeni lokushisa elibophezelayo

3.Metalize ilitshe kanye nendiza yangemuva

4.Namathisela i-target kanye ne-backplane

5.Ukupholisa

Isikhathi sokuthumela: Apr-10-2024