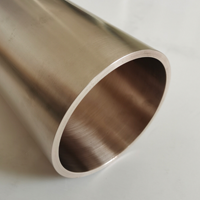

Ngokukhula kwesidingo semakethe yezinto ezihlosiwe, ziyanda izinhlobo zokuhlosiwe, ezifana nethagethi yengxubevange, okuqondiwe kwe-sputtering, okuqondiwe kwe-ceramic, njll. Iluphi ulwazi lobuchwepheshe mayelana nethagethi yethusi? Manje ake sabelane nathi ngolwazi lobuchwepheshe lwezinjongo zethusi,

1. Ukunqunywa kobubanzi nobubanzi bokubekezelela

Ngokuya ngezidingo zangempela, okuqondiwe kukhopha kudinga ukunemba okuphezulu kokubukeka, futhi okuhlosiwe okunezicaciso ezithile nokuchezuka kunikezwa ngokuya ngezidingo zamakhasimende.

2. Izidingo zokuhlanzeka

Izidingo zokuhlanzeka zinqunywa ngokuyinhloko ngokuvumelana nokusetshenziswa kwamakhasimende futhi zisekelwe ekwanelisekeni ngezidingo zamakhasimende.

3. Izidingo ze-Microstructure

① Usayizi wokusanhlamvu: usayizi wokusanhlamvu wethagethi uthinta ukusebenza kwe-sputtering kwethagethi. Ngakho-ke, usayizi wokusanhlamvu usekelwe ngokuyinhloko ezidingweni zokusetshenziswa kwekhasimende, ngochungechunge lokwelashwa kokushisa komgunyathi ukuze kuhlangatshezwane nezidingo zomsebenzisi.

② Isiqondiso se-Crystal: ngokuvumelana nezici zesakhiwo sethagethi yethusi, izindlela zokwakheka ezihlukene zamukelwa, futhi inqubo yokwelapha ukushisa ilawulwa ngokuvumelana nezidingo zomsebenzisi.

4. Izidingo zekhwalithi yokubukeka

Ingaphezulu lethagethi kumele lingabi nezinto ezidala ukusetshenziswa kabi, futhi ikhwalithi yenqubo yokufafaza kufanele iqinisekiswe ngokuya ngezidingo zekhasimende.

5. Izidingo ze-welding bond ratio

Uma ithagethi yethusi ishiselwe nezinye izinto ngaphambi kokufakaza, ukuhlolwa kwe-ultrasonic kufanele kwenziwe ngemva kokushisela ukuze kuqinisekiswe ukuthi indawo engahlanganisi kokubili ingu-≥ 95%, ihlangabezana nezidingo zokuphalaza kwamandla aphezulu ngaphandle kokuwa. Ukuhlolwa kwe-Ultrasonic akudingekile ohlotsheni lwe-in-one.

6. Izidingo zekhwalithi yangaphakathi

Uma kubhekwa izimo zesevisi zalokho okuhlosiwe, okuhlosiwe kudingeka kungabi nasici njengama-pores kanye ne-inclusions. Kunqunywa ngokuxoxisana nekhasimende ngokwezidingo zangempela.

Ngemuva kokuthi okuhlosiwe kuhlanzwe kahle ukuze kuqinisekiswe ukuthi indawo ehlosiwe ayinakho ukungcola nokunamathiselwe kwezinhlayiyana, i-vacuum igcwele ngokuqondile ngokuvumelana nezidingo zamakhasimende.

Isikhathi sokuthumela: Jul-05-2022