Yiniingxubevange yethusi zinc(CuZn) sputtering target ?

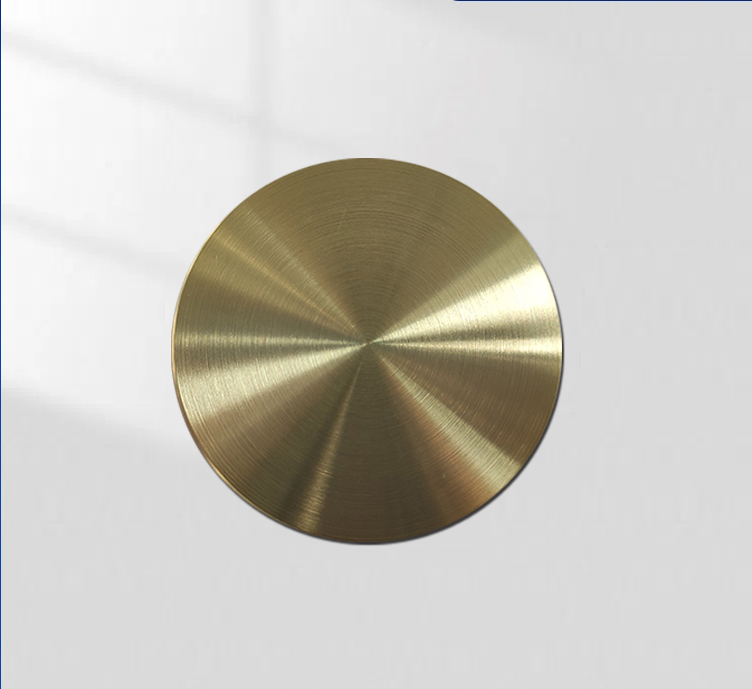

Ithagethi ye-copper zinc sputtering iyithagethi etholwe ngokuncibilikisa i-copper ehlanzekile kakhulu kanye ne-zinc, eyaziwa nangokuthi i-brass sputtering target. I-Copper Zinc Alloy Sputtering Target iyizinto ezinhle kakhulu zokuphalaza embonini yokuhlanganisa i-vacuum.

Yiziphi izinzuzo ze-copper kanye ne-zinc targets?

Okuhlosiwe kwe-Copper kanye ne-zinc kuzuze ifa lezinye izici ezinhle kakhulu zethusi, njengokuhamba kahle kukagesi kanye ne-thermal conductivity ephezulu. I-conductivity ephezulu yenza izinhloso zethusi ne-zinc zidlale indima ebalulekile ekukhiqizeni izindlela zokuqhuba kumishini kagesi, kuyilapho ukuhanjiswa okuphezulu kwe-thermal kusiza ukudlulisa ukushisa ngokuphumelelayo ngesikhathi sokusetshenziswa, ukunciphisa ukukhiqizwa kwezindawo ezishisayo, nokuthuthukisa ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo.

Ithagethi ye-Copper-zinc inethuba elibanzi lesicelo emikhakheni eminingi ngenxa yezinzuzo zayo zokuhlanzeka okuphezulu, ukufana okuhle, ukulungiselela okulula, ukusebenza kahle kokuguqulwa okuphezulu kanye nokuguquguquka.

Yiziphi izimo zokusetshenziswa kokuhlosiwe kwethusi ne-zinc?

1.Imboni ye-elekthronikhi: Okuhlosiwe kwe-Copper ne-zinc kuthatha isikhundla esibalulekile embonini ye-electronics. Lapho ulungiselela amafilimu amancane, angasetshenziselwa i-transistor metallization, i-capacitor electrode, njll. Lezi zinhlelo zokusebenza zibalulekile kwikhwalithi yamasekhethi ahlanganisiwe kanye nokukhiqizwa kwefilimu encane. Ngakho-ke, ikhwalithi yethusi ne-zinc target ithinta ngokuqondile ukusebenza nokuthembeka komkhiqizo wokugcina we-electronic.

I-2.Izinto zokugqoka: Izinhloso ze-Copper kanye ne-zinc nazo zisetshenziswa kabanzi emkhakheni wezinto zokugqoka. Ukuhlanzeka kwayo okuphezulu nokufana kwayo kuyenza ibe yinto ekahle yokulungisa ama-coatings asezingeni eliphezulu. Kungakhathaliseki ukuthi kuzinhlanganisela zensimbi, izinto ezimelana nezinga lokushisa eliphezulu noma emikhiqizweni yokuhlobisa ephezulu, okuqondiwe kwekhopha nezinc kungadlala ukusebenza okuhle kakhulu.

Amaseli e-3.olar: Ngokuthuthuka okusheshayo kwamandla avuselelekayo, isidingo sezinhloso zethusi ne-zinc emkhakheni wamaseli elanga nawo anda. Izinhloso zethusi ne-zinc zidlala indima ebalulekile ekukhiqizeni amaseli elanga, okusiza ukuthuthukisa ukusebenza kahle kokuguqulwa kwe-photoelectric kanye nempilo yesevisi yamaseli.

4.ther izinhlelo zokusebenza: Ngaphezu kwalokho, okuhloswe ngethusi ne-zinc kusetshenziswa futhi embonini yokugcina ulwazi, njenge-hard disk, ikhanda lamagnetic, i-optical disc neminye imikhiqizo. Ngesikhathi esifanayo, embonini yokubonisa isicaba, okuhlosiwe kwethusi kanye ne-zinc nakho kusetshenziselwa kabanzi ekwenzeni i-liquid crystal display (LCD) kanye nemikhiqizo ye-plasma display (PDP).

Iyini inqubo yokukhiqiza ithusi ne-zinc target?

1.Ukulungiswa kwempahla eluhlaza: Okokuqala, khetha ithusi elihlanzekile ne-zinc njengezinto zokusetshenziswa. Lezi zinto zokusetshenziswa zihlolwa ngokuqinile futhi zihlolwe ukuze kuqinisekiswe ukuthi ikhwalithi yazo nobumsulwa buhlangabezana nezidingo zokukhiqiza.

2.Ukuncibilika kanye nokuxuba: Izinto zokusetshenziswa zethusi ezilungisiwe nezinc zifakwa esithandweni esincibilikayo ngengxenye ethile ukuze zincibilike. Enkambweni yokuncibilika, ngokulawula izinga lokushisa kanye nesikhathi, ithusi ne-zinc kuxutshwe ngokugcwele futhi kufinyelele esimweni esifanayo ukuze kwakhiwe i-alloy yethusi-zinc.

3.Ukubunjwa nokubunjwa: Ingxube yethusi encibilikisiwe kanye ne-zinc alloy ithululelwa ekubunjweni kokubunjwa nokubunjwa. Lesi sinyathelo sidinga ukulawula okunembile kwesivinini sokusakaza nezinga lokushisa ukuze kuqinisekiswe umumo ofunekayo nosayizi wethagethi.

I-4.Ukucubungula nokwelashwa kokushisa: ukucubungula nokwelashwa kokushisa kwe-cast cast kanye nezinhloso ze-zinc. Lokhu kuhlanganisa ukusika, ukugaya, ukupholishwa nezinye izinqubo zokususa ukungcola okungaphezulu kanye namaphutha futhi kuthuthukiswe ukuphela kanye nokucaba kokuhlosiwe. Ngesikhathi esifanayo, i-microstructure kanye nezakhiwo ze-target zingathuthukiswa ngokuqhubekayo ngokwelashwa kokushisa.

Ukuhlolwa nokulawulwa kwekhwalithi: Kuyo yonke inqubo yokukhiqiza, okuhloswe ngethusi ne-zinc kuhlolwa futhi kulawulwa ngokuqinile. Lokhu kuhlanganisa ukuhlaziywa kokubhaliwe, ukuhlola ukuminyana, ukuhlola ubulukhuni, njll., ukuze kuqinisekiswe ukuthi ikhwalithi nokusebenza kokuhlosiwe kuhlangabezana nezindinganiso zokukhiqiza.

5.Ukuhlanza nokupakisha.

Isikhathi sokuthumela: Apr-25-2024