Ama-alloys asekelwe kusiliva nezinye izinsimbi. Kunezinhlobo eziningi zama-alloys esiliva, okubaluleke kakhulu kuzo: ama-alloys esiliva-ethusi, ama-alloys esiliva-magnesium, ama-alloys esiliva-nickel, ama-alloys esiliva-tungsten, ama-alloys e-iron-iron nama-alloys esiliva-cerium.

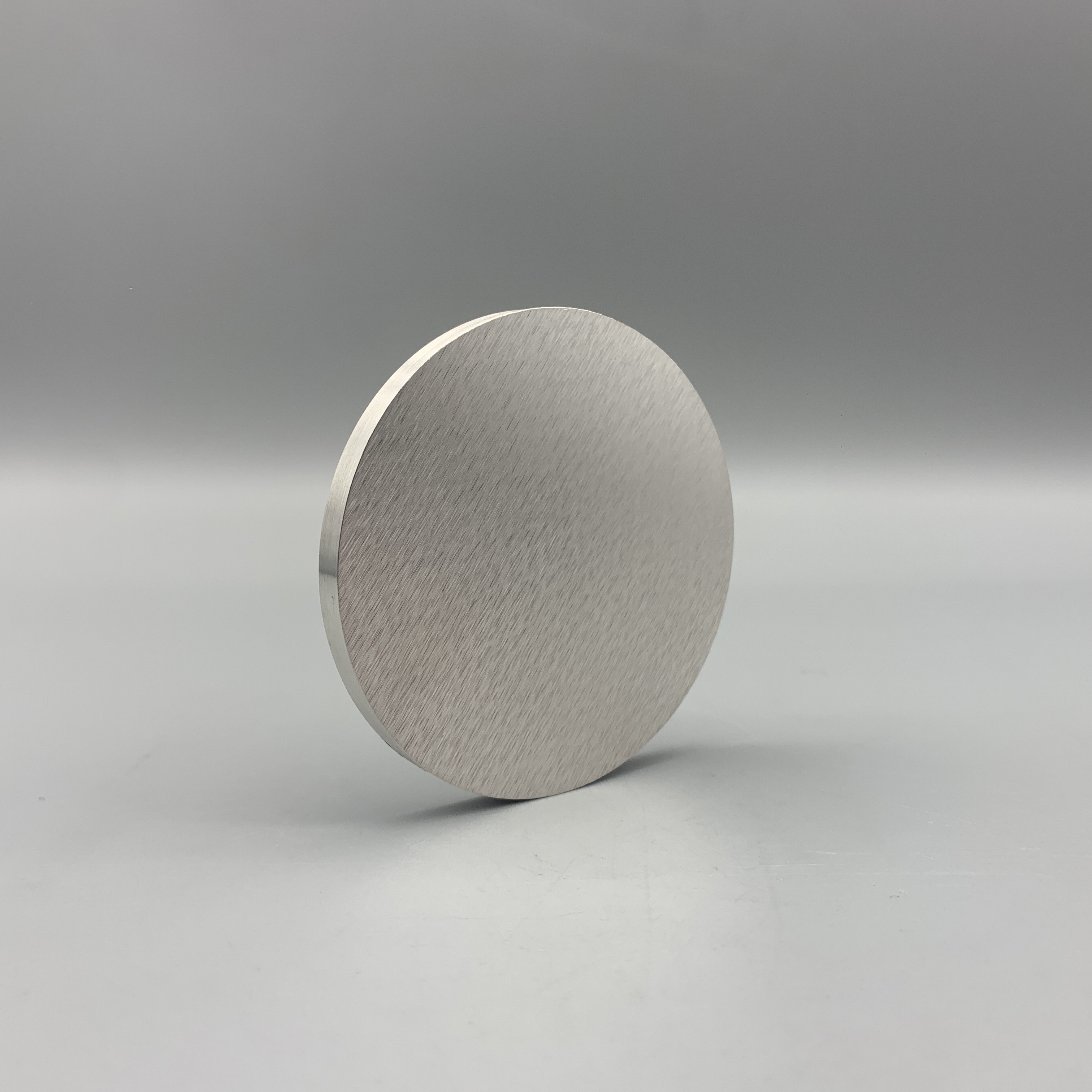

Izinto zensimbi eziyigugu ezinesiliva njengengxenye eyinhloko. Ngokuvamile sebenzisa isiliva elimsulwa noma isiliva elimsulwa eliphakeme (99.9*** ngenhla) njengezinto zokusetshenziswa, kufanele kugwenywe i-bismuth, umthofu, i-antimoni nokunye ukungcola okuyingozi. Isiliva lingakhiwa ngezinto eziningi kusixazululo esiqinile, izinhlanganisela ze-intermetallic noma isigaba esimaphakathi, kanye nezinhlobo eziningi zezinto ezihlanganisiwe (ingxubevange yamanga). Ngokuya ngezidingo, zingenziwa zibe kanambambili, i-ternary noma i-polyalloys. Ama-alloys esiliva asetshenziswa kabanzi ezindaweni eziningi zobuchwepheshe bezimboni.

Izicelo eziyinhloko zama-alloys esiliva yilezi:

(1) izinto zokubeka ezisekelwe esiliva, ikakhulukazi ama-alloys esiliva-ithusi-zinc njengesisekelo sokwakheka kochungechunge lwe-alloy, njengohlelo lwe-AgCuZn, uhlelo lwe-AgCuZnCd, uhlelo lwe-AgCuZnNi; i-alloy yesiliva-nickel, i-alloy yesiliva-yethusi;

Iqukethe 90% isiliva kanye 10% ingxubevange yethusi ebizwa currency silver, melting point 875 ℃; equkethe u-80% wesiliva no-20% wengxube yethusi ebizwa ngokuthi isiliva yomsebenzi omuhle, indawo encibilikayo 814 ℃; equkethe u-40% noma u-60% wesiliva nethusi, i-zinc, ama-cadmium alloys abizwa nge-silver solder, indawo yokuncibilika enkulu kuno-600 ℃. Isetshenziswa kakhulu ukuxhuma izidingo zamandla aphezulu emikhiqizo yensimbi.

(2) izinto zokuxhumana ezisekelwe esiliva, ikakhulukazi ingxubevange yesiliva-copper (AgCu3, AgCu7.5), kanye nengxube ye-silver-cadmium oxide nengxube ye-nickel yesiliva;

(3) isiliva-based ukumelana izinto, isiliva manganese tin ingxubevange ukumelana i-coefficient okusesilinganisweni, ukumelana lokushisa i-coefficient iphansi, amandla ethusi ezishisayo mancane, ingasetshenziswa njengendlela resistor standard futhi potentiometer mazombezombe materials; isiliva molybdenum alloy, isiliva tungsten ingxubevange, isiliva ferroalloy, isiliva cadmium alloy;

(4) izinto zokucwenga ezisekelwe esiliva, ingxubevange yesiliva-tin evame ukusetshenziswa AgSn3 ~ 5, AgPb0.4 ~ 0.7, AgPd3 ~ 5 njalonjalo;

5 yizinto ezingcono kakhulu ze-veneer. I-Silver amalgam AgxHg, okuqinile okuqinile okuqinile okumhlophe okungalingani. Ukubunjwa kwayo kuyahlukahluka kuye ngokuthi izinga lokushisa lokubunjwa; I-Ag13Hg (445°C), Ag11Hg (357°C), Ag4Hg (302°C), AgHg2 (ngaphansi kuka-300°C)

Izakhiwo ze-Silver alloy ziyathuthuka.

Isiliva lithambile ngokwedlulele futhi kulula ukusebenza. Ukuze kuthuthukiswe amandla nokuqina kwayo futhi kwandise ukumelana kwayo nokugqoka, kudala abantu banezela ithusi esiliva ukuze benze ama-alloys esiliva-ethusi, asetshenziselwa ubucwebe, i-tableware nezinhlamvu zesiliva. Ukuze uthuthukise ukusebenza kwe-alloy yesiliva-yethusi, ngokuvamile engeza i-nickel, i-beryllium, i-vanadium, i-lithium kanye nelinye iqembu lesithathu lezinto zibe yi-ternary alloys. Ngaphezu kwalokho, kunezinye izakhi eziningi ezingezwe esiliva nazo zingadlala indima ekuqiniseni.

Nakuba isiliva inert in the organic emkhathini, kodwa kulula ukuba sulfure-aqukethe umkhathi ukugqwala kanye sulfide. Ukuthuthukiswa kokumelana ne-sulfide yesiliva kubuye kube ngezindlela ze-alloying, njengokwengezwa kwegolide ne-palladium kunganciphisa izinga lokukhiqiza ifilimu ye-sulfide yesiliva. Ngaphezu kwalokho, izakhi eziningi zensimbi eziyisisekelo ezifana ne-manganese, i-antimony, ithini, i-germanium, i-arsenic, i-gallium, i-indium, i-aluminium, i-zinc, i-nickel, i-vanadium ingena esiliva ingathuthukisa izakhiwo zayo zokulwa ne-sulfuration. Izinto zokuxhumana zikagesi ezisekelwe esiliva ziyizinhlobo eziningi, kunesimo se-alloy, zikhona futhi ezisetshenziswa ezindleleni ze-powder metallurgy ezenziwe nge-alloy yamanga, inhloso ukuqinisa, ukumelana nokugqoka nokuthuthukisa izakhiwo zokuxhumana zikagesi.

Kuhunyushwe nge-DeepL.com (inguqulo yamahhala)

Isikhathi sokuthumela: Mar-07-2024