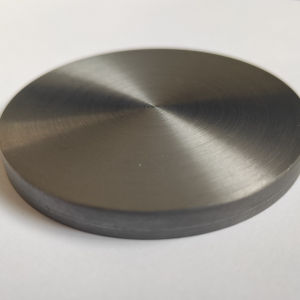

I-TiSi Sputtering Ithagethi ePhezulu Ukucoceka okuPhakamileyo kweFilimu yePvd yoKutyabeka ngokweSiko

I-Titanium Silicon

Ividiyo

Inkcazo ekujoliswe kuyo ye-Titanium Silicon Sputtering

Ukugquma kweNitride enzima kakhulu kunokusekwa xa i-Titanium Silicon idityaniswe negesi yeNitrojeni ngexesha lenkqubo yokubeka. I-Silicon element ekhoyo iqinisekisa ukuziphatha okuphezulu kwe-oxidation, ngelixa i-Titanium - ukuqina. Inokubonisa ipropathi egqwesileyo yokumelana nokunxiba nokuba kumaqondo obushushu aphezulu kakhulu. Izixhobo zokusika ezifakwe nge-TiSiN yokugqoka zifanelekile kwi-speed-speed and hard milling, ngokukodwa kwi-cutting cut dry, kwaye inokujongana nezinye i-alloys eziphezulu, njenge-Nickel kunye ne-Titanium base alloys.

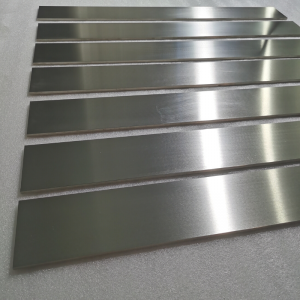

Iithagethi zethu eziqhelekileyo zeTiSi kunye neempawu zazo

| Ti-15Sie% | Ti-20Sie% | Ti-25Sie% | Ti-30Sie% | |

| Ucoceko (%) | 99.9 | 99.9 | 99.9 | 99.9 |

| Ukuxinana(g/cm3) | 4.4 | 4.35 | 4.3 | 4.25 |

| Gimvula Ubungakanani(µm) | 200/100 | 100 | 100 | 100 |

| Inkqubo | IVAR/HIP | I-HIP | I-HIP | I-HIP |

Inkampani yethu ineminyaka emininzi yamava okwenza iithagethi ze-sputtering zezixhobo zokusika umngundo. I-Ti-15Si kwi-%, eyenziwe nge-vacuum melting, inesakhiwo esilinganayo, ukucoceka okuphezulu kunye nomxholo wegesi ophantsi. Ngaphandle koko, sinikezela nge-Ti-15Si kwi-%, i-Ti-20Si kwi-% kunye ne-Ti-25Si kwi-% eveliswa ngamandla esinyithi. Iithagethi zethu ze-TiSi zineempawu ezigqwesileyo zoomatshini, ezibenza ukuba bangachaphazeleki kukuqhekeka kunye nokusilela kwesakhiwo.

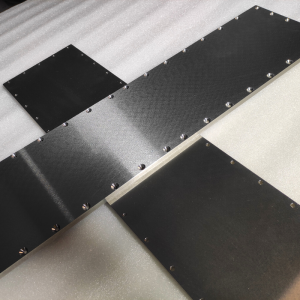

I-Titanium Silicon Sputtering Target Packaging

Ithagethi yethu ye-Titanium Silicon sputter iphawulwe ngokucacileyo kwaye ibhalwe ngaphandle ukuqinisekisa ukuchongwa okusebenzayo kunye nolawulo lomgangatho. Ukhathalelo olukhulu luthathwa ukuphepha nawuphi na umonakalo onokuthi ubangelwe ngexesha lokugcinwa okanye ukuthuthwa.

Fumana uQhagamshelwano

Iithagethi ze-RSM ze-Titanium Silicon sputtering zicoceke kakhulu kwaye ziyafana. Zifumaneka ngeentlobo ngeentlobo, ucoceko, ubukhulu, kunye namaxabiso. Sisebenza ngokukhethekileyo ekuveliseni izinto zokugquma iifilimu ezicocekileyo ezicocekileyo ezisebenza ngokugqwesileyo kunye nobuninzi obunokubakho kunye nobukhulu obuncinci obunokubakho obuqhelekileyo obunokubakho bokusetyenziswa ekugqumeni kokungunda, umhombiso, iinxalenye zemoto, iglasi ephantsi ye-E, isekethe edibeneyo ye-semi-conductor, ifilimu encinci. ukumelana, umboniso wegraphic, i-aerospace, ushicilelo lwemagnethi, isikrini sokuchukumisa, ifilim encinci yebhetri yelanga kunye nezinye iinkqubo zokubeka umphunga (PVD). Nceda usithumelele umbuzo malunga namaxabiso angoku kwiithagethi ze-sputtering kunye nezinye izinto zokubeka ezingadweliswanga.