I-TiAl Sputtering Ithagethi ePhezulu Ukucoceka okuPhakamileyo kweFilimu yePvd yoKutyabeka ngokweSiko

I-Titanium Aluminium

Ividiyo

Inkcazo ekujoliswe kuyo yi-Titanium Aluminium Sputtering

Imfuno yomgangatho ojoliswe kuyo wokugquma kwe-sputter iphezulu kunelo shishini lezinto zemveli. I-microstructure efanayo yethagethi ichaphazela ngokuthe ngqo ukusebenza kwe-sputtering. Sinenkqubo yokulawula umgangatho ogqityiweyo kwaye sikhetha izinto ezicocekileyo zokucoceka kwaye zixutywe ngokucokisekileyo ukuze kuqinisekiswe ukufana. Ithagethi ye-Titanium Aluminiyam ye-sputtering ye-aluminiyam iveliswa ngendlela yokucoca i-vacuum eshushu.

Iithagethi zethu zokutshiza ze-Titanium Aluminium zinokubonelela ngokugqwesa kwe-nitride ukumelana ne-oxidation, i-Titanium aluminium nitride (TiAlN). I-TiAlN yeyona nto ikhoyo ngoku njengefilimu yezixhobo zokusika, iinxalenye ze-sliding kunye ne-tribo-coatings. Inobulukhuni obuphezulu, ukuqina, ukunxiba ukusebenza kokumelana kunye nobushushu be-oxidation.

Iithagethi zethu eziqhelekileyo zeTiAl kunye neempawu zazo

| Ti-75Al at% | Ti-70Al at% | Ti-67Al at% | Ti-60Al at% | Ti-50Al at% | Ti-30Al at% | Ti-20Al at% | Ti-14Al at% | |

| Ucoceko (%) | 99.7 | 99.7 | 99.7 | 99.7 | 99.8/99.9 | 99.9 | 99.9 | 99.9 |

| Ukuxinana(g/cm3) | 3.1 | 3.2 | 3.3 | 3.4 | 3.63/3.85 | 3.97 | 4.25 | 4.3 |

| Gimvula Ubungakanani(µm) | 100 | 100 | 100 | 100 | 100/- | - | - | - |

| Inkqubo | I-HIP | I-HIP | I-HIP | I-HIP | I-HIP/VAR | IVAR | IVAR | IVAR |

I-Titanium Aluminiyam yokuSputtering ekuJoliswe kuyo

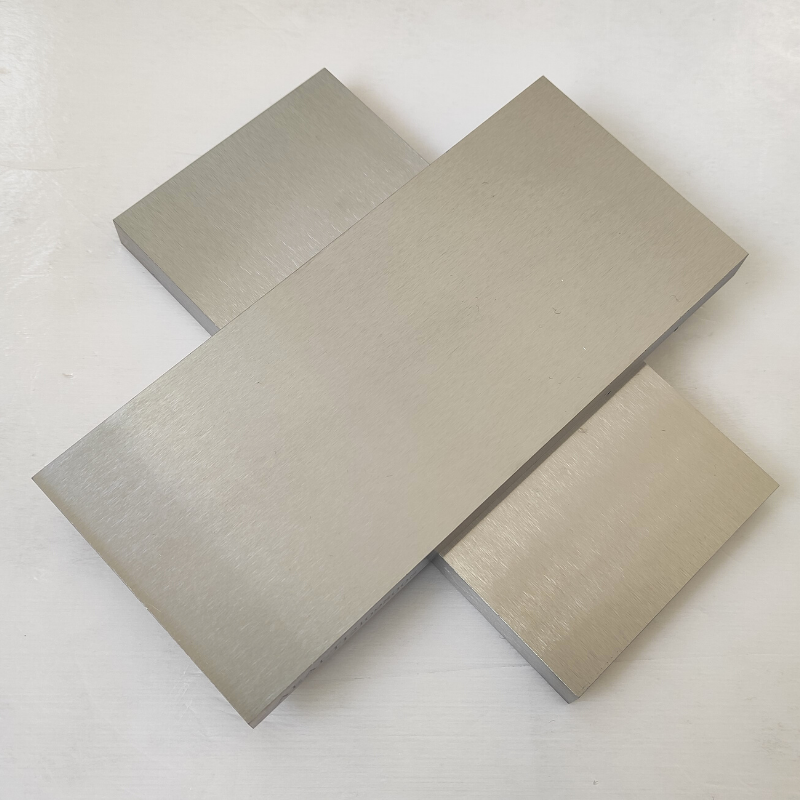

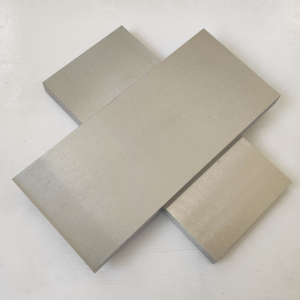

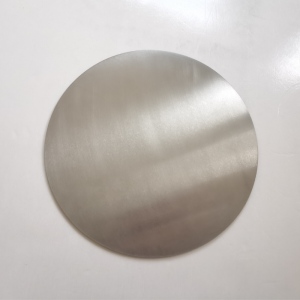

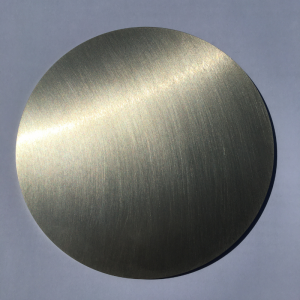

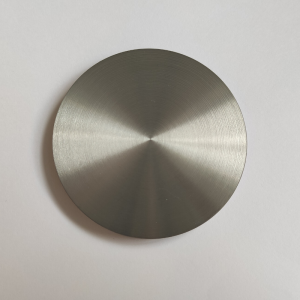

Ithagethi yethu ye-Titanium Aluminium sputter iphawulwe ngokucacileyo kwaye ibhalwe ngaphandle ukuqinisekisa ukuchongwa okusebenzayo kunye nolawulo lomgangatho. Ukhathalelo olukhulu luthathwa ukuphepha nawuphi na umonakalo onokuthi ubangelwe ngexesha lokugcinwa okanye ukuthuthwa.

Fumana uQhagamshelwano

Iithagethi ze-RSM ze-Titanium Aluminium sputtering zicoceke kakhulu kwaye ziyafana. Zifumaneka ngeentlobo ngeentlobo, ucoceko, ubukhulu, kunye namaxabiso.

Sinokubonelela ngeendlela ezahlukeneyo zejometri: iityhubhu, i-arc cathodes, iplani okanye eyenziwe ngokwezifiso, kunye noluhlu olubanzi lweAluminiyam. Iimveliso zethu zineempawu ezigqwesileyo zoomatshini, i-microstructure elinganayo, umphezulu opolishiweyo ngaphandle kokwahlulwa, iipores, okanye iintanda.

Sisebenza ngokukhethekileyo ekuveliseni izinto zokugquma iifilimu ezicocekileyo ezicocekileyo ezisebenza ngokugqwesileyo kunye nobuninzi obunokubakho kunye nobukhulu obuncinci obunokubakho obuqhelekileyo obunokubakho bokusetyenziswa ekugqumeni kokungunda, umhombiso, iinxalenye zemoto, iglasi ephantsi ye-E, isekethe edibeneyo ye-semi-conductor, ifilimu encinci. ukumelana, umboniso wegraphic, i-aerospace, ushicilelo lwemagnethi, isikrini sokuchukumisa, ifilim encinci yebhetri yelanga kunye nezinye iinkqubo zokubeka umphunga (PVD). Nceda usithumelele umbuzo malunga namaxabiso angoku kwiithagethi ze-sputtering kunye nezinye izinto zokubeka ezingadweliswanga.