Ngaphambili, abathengi abaninzi babuza oogxa be-RSM Technology kwiSebe malunga ne-titanium alloy. Ngoku, ndingathanda ukukushwankathela la manqaku alandelayo malunga nokuba yeyiphi intsimbi ye-titanium alloy eyenziwe ngayo. Ndiyathemba ukuba banokukunceda.

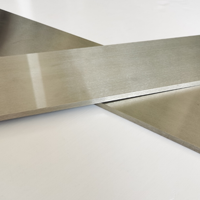

I-Titanium alloy yi-alloy eyenziwe nge-titanium kunye nezinye izinto.

I-Titanium yikristale ene-homogeneous heterogeneous, enendawo yokunyibilika eyi-1720 ℃. Xa iqondo lobushushu lingaphantsi kwama-882 ℃, inolwakhiwo olusondeleleneyo olunehexagonal lettice, ebizwa ngokuba yi-α Titanium; Inomzimba ogxile kwi-cubic structure ngaphezulu kwe882 ℃, ebizwa ngokuba yi-β Titanium. Ukuthatha inzuzo yeempawu ezahlukeneyo zezi zakhiwo zimbini zingasentla ze-titanium, izinto ezifanelekileyo ze-alloy zongezwa ukuba zitshintshe ngokuthe ngcembe ubushushu benguqu yesigaba kunye nomxholo wesigaba sokufumana i-titanium alloys enezakhiwo ezahlukeneyo. Kwiqondo lobushushu begumbi, i-titanium alloys ineentlobo ezintathu zezakhiwo ze-matrix, kunye ne-titanium alloys nazo zohlulwe zibe ziindidi ezintathu ezilandelayo: α Ingxubevange ( α + β) Ingxubevange kunye ne-β Alloy. E-China, iboniswa yi-TA, TC kunye ne-TB ngokulandelanayo.

ialloyi yetitanium

Yi-alloy yesigaba esinye esinesisombululo esiqinileyo sesigaba se-α, isakhiwo esizinzile, ukuxhathisa ukunxiba okuphezulu kune-titanium ecocekileyo, ukuxhathisa okunamandla kwe-oxidation. Phantsi kobushushu be-500 ℃ ~ 600 ℃, isawagcina amandla ayo kunye nokumelana nokunyuka, kodwa ayinakomelezwa ngonyango lobushushu, kwaye amandla ayo obushushu begumbi akaphezulu.

β ingxubevange yetitanium

Yi-β I-alloy yesigaba esinye esenziwe sisisombululo esiqinileyo sesigaba sinamandla aphezulu ngaphandle konyango lobushushu. Emva kokucima kunye nokuguga, i-alloy iqiniswa ngakumbi, kwaye amandla okushisa kwegumbi anokufikelela kwi-1372 ~ 1666 MPa; Nangona kunjalo, ukuzinza kwe-thermal kubi kwaye akufanelekile ukusetyenziswa kumaqondo aphezulu.

α+β ingxubevange yetitanium

I-alloy yesigaba esiphindwe kabini kunye neempawu ezintle ezibanzi, ukuzinza okulungileyo kwesakhiwo, ukuqina okulungileyo, iplastiki kunye neempawu zokuguqulwa kobushushu obuphezulu. Ingasetyenziselwa ukulungiswa koxinzelelo olushushu, ukucima kunye nokuguga ukuqinisa i-alloy. Amandla emva kokunyangwa kobushushu malunga ne-50% ~ 100% ephezulu kunoko emva kokuba i-annealing; Amandla okushisa aphezulu, anokusebenza kwi-400 ℃ ~ 500 ℃ ixesha elide, kwaye ukuzinza kwayo kwe-thermal kungaphantsi kwe-alpha Titanium alloy.

Phakathi kwee-alloys ezintathu ze-titanium α i-Titanium alloys kunye ne-α + β Titanium alloy; I-alloy ye-Titanium inokusebenza kakuhle, i-α+ P ye-Titanium alloy ithatha indawo yesibini, i-β Titanium alloy ayilunganga. α Ikhowudi ye-titanium alloy yi-TA, β Ikhowudi ye-titanium alloy yi-TB, α+β Ikhowudi ye-titanium alloy yi-TC.

I-alloys ye-Titanium inokwahlulwa ibe yi-alloys ekwazi ukumelana nobushushu, i-alloys enamandla kakhulu, i-corrosion resistant alloys (i-titanium molybdenum, i-titanium palladium alloys, njl.) ) ngokwezicelo zabo.

Ukunyanga ukushisa: i-titanium alloy inokufumana ukubunjwa kwesigaba esahlukileyo kunye nesakhiwo ngokulungelelanisa inkqubo yonyango lokushisa. Ngokuqhelekileyo kukholelwa ukuba i-fine equiaxed microstructure ineplastiki efanelekileyo, ukuzinza kwe-thermal kunye namandla okukhathala; Isakhiwo se-acicular sinamandla amakhulu okuqhekeka, amandla okukhwela kunye nokuqina kwe-fracture; I-Mixed equiaxed kunye ne-acicular tissues zinemisebenzi engcono ebanzi

Ixesha lokuposa: Oct-26-2022