Sonke siyazi ukuba i-sputtering yenye yetekhnoloji ephambili yokulungiselela izinto zefilimu. Isebenzisa ii-ion eziveliswe ngumthombo we-ion ukukhawulezisa udibaniso kwi-vacuum ukwenza umqadi we-ion onesantya esiphezulu, ibhombu indawo eqinileyo, kunye nee-ion zotshintshiselwano lwamandla e-kinetic kunye neeathom kumphezulu oqinileyo, ukuze iiathom kwindawo eqinileyo. umphezulu shiya okuqinileyo kunye nediphozithi kumphezulu we-substrate. Ibhombu eqinileyo yimathiriyeli ekrwada yokufaka ifilim ngokutshiza, ebizwa ngokuba yithagethi yokutshiza.

Iindidi ezahlukeneyo zezixhobo zefilimu ezitshisiweyo zisetyenziswe ngokubanzi kwiisekethe ezidibeneyo ze-semiconductor, imidiya yokurekhoda, umboniso weplani, isixhobo kunye ne-die surface coating njalo njalo.

Iithagethi ze-sputtering zisetyenziswa ikakhulu kumashishini e-elektroniki kunye nolwazi, njengeesekethe ezidibeneyo, ukugcinwa kolwazi, imiboniso yekristale yolwelo, iinkumbulo ze-laser, izixhobo zokulawula i-elektroniki, njl. Inokusetyenziswa kwakhona kwintsimi yokugqoka iglasi; Isenokusetyenziswa kwizinto ezikwaziyo ukunxiba, ukumelana nobushushu obuphezulu be-corrosion, iimveliso zokuhombisa eziphezulu kunye namanye amashishini.

Kukho iintlobo ezininzi zeethagethi ze-sputtering, kwaye kukho iindlela ezahlukeneyo zokuhlelwa kweethagethi:

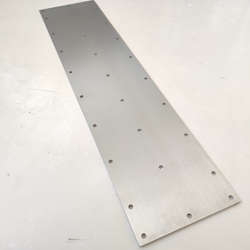

Ngokutsho kokubunjwa, kunokwahlulwa kwithagethi yesinyithi, i-alloy target kunye ne-ceramic compound target.

Ngokwemilo, inokwahlulwa ibe yithagethi ende, ithagethi yesikwere kunye nethagethi ejikelezayo.

Iyakwazi ukwahlula kwithagethi ye-microelectronic, i-target ye-magnetic yokurekhoda, i-optical disk target, i-target yensimbi exabisekileyo, i-target resistance target, i-film resistance target, i-target ye-conductive film, ithagethi yokuguqulwa kwendawo, i-mask target, i-decorative layer target, i-electrode target kunye nezinye iithagethi ngokwenkalo yesicelo.

Ngokwezicelo ezahlukeneyo, inokohlulwa ibe kuthagethi lwe-ceramic enxulumene ne-semiconductor, ukurekhodwa okuphakathi kwethagethi ye-ceramic, iithagethi ze-ceramic zokubonisa, iithagethi ze-ceramic ze-superconducting kunye neethagethi ezinkulu ze-ceramic ze-magnetoresistance.

Ixesha lokuposa: Jul-29-2022