Ngokunyuka kwemfuno yemarike yeethagethi, kukho iintlobo ezininzi zeethagethi, ezifana neethagethi ze-alloy, iithagethi ze-sputtering, iithagethi ze-ceramic, njl. Ngoku masabelane ngolwazi lobugcisa bokujoliswe kuko kobhedu kunye nathi,

1. Ukumiselwa kobukhulu kunye noluhlu lokunyamezela

Ngokweemfuno zangempela, iithagethi zobhedu zifuna ukuchaneka okuphezulu kwemilinganiselo yembonakalo, kunye neethagethi ezineenkcazo ezithile kunye nokuphambuka zinikezelwa ngokweemfuno zabathengi.

2. Iimfuno zokucoceka

Iimfuno zokucoceka zigqitywa ngokusetyenziswa kwabathengi kwaye zisekelwe ekwaneliseni iimfuno zabathengi.

3. Iimfuno zeMicrostructure

① Ubungakanani bokudla okuziinkozo: ubungakanani obuziinkozo koko kujoliswe kuko kuchaphazela ukusebenza kokuchaphaza koko kujoliswe kuko. Ngoko ke, ubukhulu bengqolowa busekelwe ikakhulu kwiimfuno zomthengi zokusetyenziswa, ngokusebenzisa uthotho lonyango lobushushu lokubumba ukuhlangabezana neemfuno zomsebenzisi.

② Ulwalathiso lwe-Crystal: ngokweempawu zesakhiwo sethagethi yobhedu, iindlela ezahlukeneyo zokubumba ziyamkelwa, kwaye inkqubo yonyango lokushisa ilawulwa ngokweemfuno zomsebenzisi.

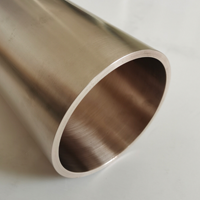

4. Iimfuno zomgangatho wembonakalo

Umphezulu wenjongo kufuneka ukhululeke kwizinto ezibangela ukusetyenziswa kakubi, kwaye umgangatho wenkqubo yokutshiza kufuneka uqinisekiswe ngokweemfuno zomthengi.

5. Iimfuno ze-welding bond ratio

Ukuba ithagethi yobhedu idityaniswe nezinye izinto ngaphambi kokuba i-sputtering, ukuhlolwa kwe-ultrasonic kufuneka kwenziwe emva kwe-welding ukuqinisekisa ukuba indawo engabandakanyiyo yezimbini i-≥ 95%, ukuhlangabezana neemfuno zokutshiza kwamandla aphezulu ngaphandle kokuwa. Uvavanyo lwe-Ultrasonic alufuneki kulo lonke uhlobo olunye.

6. Iimfuno zomgangatho wangaphakathi

Ngenxa yeemeko zenkonzo ekujoliswe kuyo, ekujoliswe kuko kufuneka kungabi naziphene ezifana neepores kunye nokubandakanywa. Kumiselwa ngokuthethathethana nomthengi ngokweemfuno zangempela.

Emva kokuba ithagethi ihlanjululwe ngokucokisekileyo ukuze kuqinisekiswe ukuba indawo ekujoliswe kuyo ayinayo inkunkuma kunye ne-particle attachments, i-vacuum ngqo ipakishwe ngokweemfuno zabathengi.

Ixesha lokuposa: Jul-05-2022