Kwiminyaka yakutshanje, kunye nenkqubela phambili yeteknoloji yesekethe edibeneyo (IC), izicelo ezinxulumene neesekethe ezidibeneyo ziye zaphuhliswa ngokukhawuleza. Ukucoceka okuphezulu kwe-aluminium alloy sputtering target, njengento exhasayo ekuveliseni i-interconnect yentsimbi yesekethe edibeneyo, ibe ngumxholo oshushu kuphando lwasekhaya lwakutsha nje. umhleli we-RSM uya kusibonisa iimpawu zokucoceka okuphezulu kwe-aluminium alloy sputtering target.

Ukuze kuphuculwe ngakumbi ukusebenza kakuhle kwe-sputtering ye-magnetron sputtering target kunye nokuqinisekisa umgangatho weefilimu ezigciniweyo, inani elikhulu leemvavanyo libonisa ukuba kukho iimfuno ezithile zokuqulunqa, i-microstructure kunye nokuqhelaniswa kweenkozo ze-ultra-high purity aluminium alloy sputtering target.

Ubungakanani obuziinkozo kunye nokujoliswa kweenkozo ekujoliswe kuzo kunempembelelo enkulu kumalungiselelo kunye neempawu zeefilimu ze-IC. Iziphumo zibonisa ukuba izinga lokubekwa liyehla ngokunyuka kobukhulu beenkozo; Kwithagethi yokutshiza enokwakheka okufanayo, umlinganiselo wokutshiza wento ekujoliswe kuyo enobukhulu obuziinkozo obuncinane bukhawuleza kunoko bekujoliswe kuko okunobungakanani beenkozo ezinkulu; Okukhona ubungakanani obufanayo obuziinkozo koko kujoliswe kuko, kokukhona ukufana kobuninzi beefilim ezifakiweyo.

Ngaphantsi kwesixhobo esifanayo sokutshiza kunye neeparitha zenkqubo, izinga lokutshiza lethagethi ye-Al Cu yealloy liyenyuka ngokunyuka koxinaniso lwe-athomu, kodwa ngokuqhelekileyo lizinzile kuluhlu. Isiphumo sobungakanani beenkozo kwisantya sokutshiza kungenxa yokutshintsha koxinaniso lweathom kunye nokutshintsha kobungakanani beenkozo; Ireyithi yokubeka ichatshazelwa ikakhulu kukuqhelaniswa neenkozo kwithagethi yealloyi yeAl Cu. Ngesiseko sokuqinisekisa umlinganiselo (200) weendiza zekristale, ukwanda komlinganiselo (111), (220) kunye (311) iiplani zekristale ziya kwandisa izinga lokubeka.

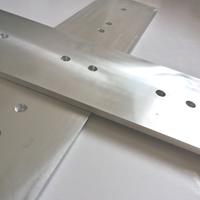

Ubungakanani beenkozo kunye nokuqhelaniswa kweenkozo kwiithagethi ze-alloy ye-aluminium ecocekileyo ye-ultra-high zihlengahlengiswa kwaye zilawulwe yi-ingot homogenization, ukusebenza okushushu kunye ne-recrystallization annealing. Ngokuphuhliswa kobukhulu be-wafer ukuya kwi-20.32cm (8in) kunye ne-30.48cm (12in), ubukhulu obujoliswe kuyo buyanda, obubeka phambili iimfuno eziphezulu ze-ultra-high purity aluminium alloy sputtering targets. Ukuze kuqinisekiswe umgangatho wefilimu kunye nesivuno, iiparitha zokulungiswa okujoliswe kuzo kufuneka zilawulwe ngokungqongqo ukwenza i-microstructure ejoliswe kuyo iyunifomu kunye ne-grain orientation kufuneka ibe namandla (200) kunye (220) i-plane textures.

Ixesha lokuposa: Jun-30-2022