I-Rich Special Material Co., Ltd. inokuvelisa iithagethi ze-aluminiyam ezicocekileyo ezicocekileyo, iithagethi ze-sputtering yobhedu, iithagethi ze-tantalum sputtering, iithagethi ze-titanium sputtering, njl. kushishino lwe-semiconductor.

Iitshiphusi zeSemiconductor zineemfuno eziphezulu zobugcisa kunye namaxabiso aphezulu ekujoliswe kuko kwe-sputtering. Iimfuno zabo zokucoceka kunye neteknoloji yeethagethi ze-sputtering ziphezulu kunezo ze-flat panel displays, iiseli zelanga kunye nezinye izicelo. Iitshiphusi zeSemiconductor zibeka imigangatho engqongqo kakhulu kubunyulu kunye ne-microstructure yangaphakathi yeethagethi ze-sputtering. Ukuba umxholo ongcolileyo wethagethi ye-sputtering uphezulu kakhulu, ifilimu eyenziwe ayikwazi ukuhlangabezana neempawu zombane ezifunekayo. Kwinkqubo ye-sputtering, kulula ukwenza amaqhekeza kwi-wafer, okubangelwa isiphaluka esifutshane okanye umonakalo wesiphaluka, ochaphazela kakhulu ukusebenza kwefilimu. Xa sithetha ngokubanzi, eyona thagethi iphezulu yokucoceka iyafuneka kwimveliso yetshiphu, edla ngokuba yi-99.9995% (5N5) okanye ngaphezulu.

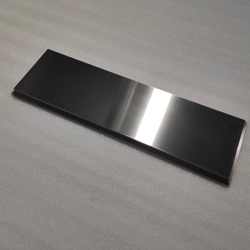

Iithagethi ze-sputtering zisetyenziselwa ukwenziwa kweengqimba zomqobo kunye nokupakisha iileya ze-wiring zetsimbi. Kwinkqubo yokwenziwa kwe-wafer, ekujoliswe kuyo kusetyenziswa ikakhulu ukwenza umaleko oqhubayo, umaleko wesithintelo kunye negridi yentsimbi yewafer. Kwinkqubo yokupakisha i-chip, i-sputtering target isetyenziselwa ukuvelisa i-metal layers, iileyile ze-wiring kunye nezinye izinto zetsimbi phantsi kwee-bumps. Nangona ubungakanani bezinto ekujoliswe kuzo ezisetyenziselwa ukwenziwa kweewafer kunye nokupakishwa kwetshiphu zincinci, ngokweenkcukacha-manani ze-SEMI, ixabiso lemathiriyeli ekujoliswe kuyo ekwenzeni iwafer kunye nenkqubo yokupakisha ibalelwa kwi-3%. Nangona kunjalo, umgangatho wethagethi ye-sputtering ichaphazela ngokuthe ngqo ukufana kunye nokusebenza kwe-conductive layer kunye ne-barrier layer, ngaloo ndlela ichaphazela isantya sokuhambisa kunye nokuzinza kwe-chip. Ke ngoko, ujoliso lwe-sputtering sesinye sezixhobo ezisisiseko zokuvelisa i-semiconductor

Ixesha lokuposa: Nov-16-2022