I-AlSnCu Sputtering Ithagethi ePhezulu Ukucoceka okuPhakamileyo kweFilimu yePvd yoKutyabeka ngokweSiko

IAluminiyam yeTin Copper

Ividiyo

IAluminiyam yeTin yeCopper Sputtering Inkcazo ekujoliswe kuyo

Iithagethi zeAluminiyam yeTin Copper zidla ngokusetyenziselwa ukugquma injini, ngenxa yokungaguquguquki kwayo okuphezulu okunikwa yinkqubo yokuqengqeleka. I-Tin ine-coefficient ephantsi ye-friction, eyona nto yokuqala yokuqwalaselwa ekusebenziseni kwayo njengento yokuthwala. I-Tin ngokwesakhiwo yintsimbi ebuthathaka, kwaye xa isetyenziswa ekuthwaleni izicelo idityaniswe neCopper kunye neAluminiyam eyongeziweyo yobulukhuni, ukomelela kunye nokumelana nokudinwa. I-aluminium ye-Tin ye-Copper i-alloy inobunzima obuphakathi, ukumelana nokunxiba okuphezulu, okwenza kube yinto efanelekileyo yokukhetha ukudibanisa iintonga kunye ne-thrust bears kwii-injini eziphezulu. Ibonisa ukuxhathisa okugqwesileyo kukudleka kweemveliso zokonakaliswa kwe-oyile kunye nokushumeka kakuhle, ngakumbi kwiindawo ezinothuli.

Iimveliso zethu eziqhelekileyo ze-AlSnCu kunye neempawu

| Al-18Sn-1Cuwt% | Al-25Sn-1Cuwt% | I-Al-49Sn-1Cuwt% | |

| Ucoceko(%) | 99.8/99.95 | 99.8/99.95 | 99.8/99.95 |

| Ukuxinana(g/cm3) | 3.1 | 3.2 | 3.95 |

| Inkqubo | Cast+ukuqengqeleka | Cast+ukuqengqeleka | Cast+ukuqengqeleka |

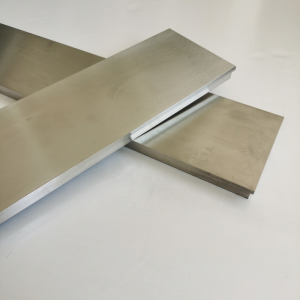

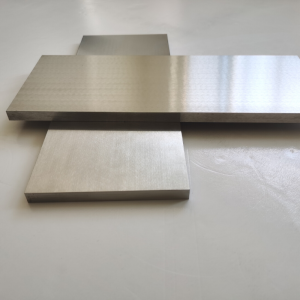

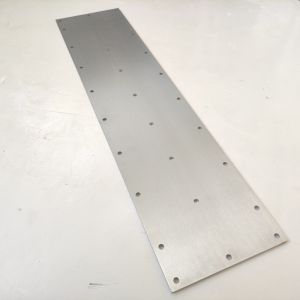

IAluminiyam yeTin yeCopper Sputtering Target Packaging

Ithagethi yethu ye-Aluminium Tin Copper sputter iphawulwe ngokucacileyo kwaye ibhalwe ngaphandle ukuqinisekisa ukuchongwa okusebenzayo kunye nolawulo lomgangatho. Ukhathalelo olukhulu luthathwa ukuphepha nawuphi na umonakalo onokuthi ubangelwe ngexesha lokugcinwa okanye ukuthuthwa.

Fumana uQhagamshelwano

Iithagethi ze-RSM's Aluminium Tin Copper sputtering ze-ultra-high purity kunye neyunifomu. Zifumaneka ngeentlobo ngeentlobo, ucoceko, ubukhulu, kunye namaxabiso. Sisebenza ngokukhethekileyo ekuveliseni izinto zokugquma iifilimu ezicocekileyo ezicocekileyo ezisebenza ngokugqwesileyo kunye nobuninzi obunokubakho kunye nobukhulu obuncinci obunokubakho obuqhelekileyo obunokubakho bokusetyenziswa ekugqumeni kokungunda, umhombiso, iinxalenye zemoto, iglasi ephantsi ye-E, isekethe edibeneyo ye-semi-conductor, ifilimu encinci. ukumelana, umboniso wegraphic, i-aerospace, ushicilelo lwemagnethi, isikrini sokuchukumisa, ifilim encinci yebhetri yelanga kunye nezinye iinkqubo zokubeka umphunga (PVD). Nceda usithumelele umbuzo malunga namaxabiso angoku kwiithagethi ze-sputtering kunye nezinye izinto zokubeka ezingadweliswanga.