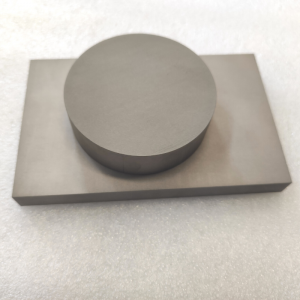

WC Tungsten Carbide

WC Tungsten Carbide

Tungsten carbide is a compound composed of tungsten and carbon, with a molecular formula of WC and a molecular weight of 195.85. The most basic form of tungsten carbide is a fine gray powder, but it can be pressed into shape through a process called sintering, used in industrial machinery, cutting tools, abrasives, armor-piercing bullets and jewelry.

The stiffness of tungsten carbide is about twice that of steel, and the Young's modulus is about 530-700 GPa (77,000 to 102,000 ksi), which is twice the density of steel, almost between lead and gold. Its hardness is comparable to that of corundum (α-Al2O3), and only cubic boron nitride and diamond powder, grinding wheels and compounds with high hardness abrasives can be used for polishing and finishing.

Tungsten carbide is a black hexagonal crystal with a metallic luster and hardness similar to diamonds. It is a good conductor of electricity and heat. Tungsten carbide is insoluble in water, hydrochloric acid and sulfuric acid, but easily soluble in a mixed acid of nitric acid and hydrofluoric acid. Pure tungsten carbide is fragile, if a small amount of titanium, cobalt and other metals are added, its brittleness can be reduced. Tungsten carbide used as steel cutting tools is usually added with titanium carbide, tantalum carbide or their mixture to improve the anti-knock ability. Tungsten carbide is chemically stable. Tungsten carbide powder is used as a material for cemented carbide production.

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Tungsten Carbide Sputtering Materials according to Customers’ specifications. For more information, please contact us.