TiAlSi Sputtering Target High Purity Thin Film Pvd Coating Custom Made

Silicon ea Titanium Aluminium

Tlhaloso ea Sepheo sa Titanium Aluminium Silicon Sputtering

Titanium Aluminium Silicon sputtering target e entsoe ka tšepe ea matla.

Titanium Aluminium Silicon alloy e sebelisoang ka tloaelo ho etsa enjine ea likoloi. E na le boleng bo botle ba mocheso o phahameng le ho hanyetsa ho apara. Tšebeliso ea motsoako oa Ti-Al-Si e ka lelefatsa bophelo ba likarolo tsa enjene ka hoo e ka bang 35%. Ha e le ts'ebeliso ea eona ho sethuthuthu le lebili la likoloi, e bonts'a bokhoni bo betere, machinability, ho hanyetsa mokhathala le ho ba thata ho feta A356 Aluminium.

Motsoako oa aluminium o tiileng ka potlako o ne o ka fumanoa ka mokhoa o potlakileng oa ho tiisa o bitsoang "melt spinning", e hlahisang thepa e phahameng ha e bapisoa le motsoako o tloaelehileng oa aluminium, hammoho le microstructure e entsoeng hantle le ho fetoha habonolo ha motsoako. Ke lisebelisoa tse ka bang teng indastering ea lifofane ho nka sebaka sa Titanium base e sebelisoa ho 150-300 ℃.

Nakong ea ts'ebetso ea ho beha lipakane tsa TiAlSi, TiAlSi/TiAlSiN e ka thehoa ka bomong e le mekhahlelo e mengata ea boleng bo phahameng ba kristale e nang le li-cubic structures. Liaparo tsena tse nang le mekhahlelo e mengata li entse lisebelisoa tsena bakeng sa ho roala ka thata ho eketsa nako ea bophelo ea lisebelisoa tse sebelisoang libakeng tse thata.

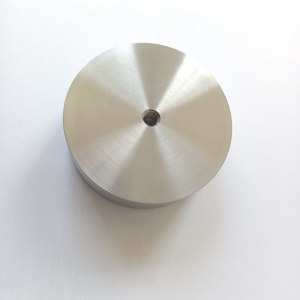

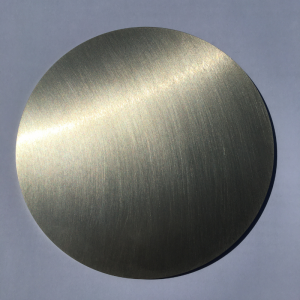

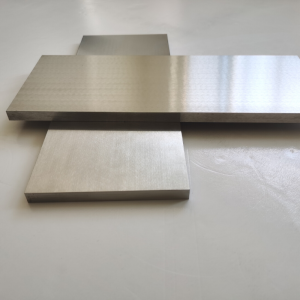

Titanium Aluminium Silicon Sputtering Target Packaging

Sepheo sa rona sa Titanium Aluminium Silicon sputter se tšoailoe ka ho hlaka le ho ngoloa ka ntle ho netefatsa boitsebiso bo nepahetseng le taolo ea boleng. Ho hlokomeloa haholo ho qoba tšenyo leha e le efe e ka bakoang nakong ea polokelo kapa ea lipalangoang.

Fumana Lebitso

Lipheo tsa RSM's Titanium Aluminium Silicon sputtering targets ke tsa bohloeki bo phahameng haholo le junifomo. Li fumaneha ka mefuta e fapaneng, purities, boholo le litheko. Re sebetsa ka ho khetheha ho hlahiseng lisebelisoa tsa ho roala filimi tse hloekileng tse tšesaane tse nang le ts'ebetso e ntle ka ho fetesisa hammoho le boholo bo phahameng ka ho fetesisa ba lijo-thollo tse ka sebelisoang ho roala hlobo, mokhabiso, likarolo tsa koloi, khalase e tlase-E, potoloho e kopaneng ea semi-conductor, filimi e tšesaane. ho hanyetsa, ponts'o ea litšoantšo, sebaka sa sefofane, ho rekota ka matla a khoheli, skrine ea ho ama, betri ea letsatsi e tšesaane ea filimi le lits'ebetso tse ling tsa 'mele tsa ho beha mouoane (PVD). Ka kopo re romelle potso mabapi le litheko tsa hajoale mabapi le lipehelo tsa sputtering le lisebelisoa tse ling tsa deposition tse sa thathamisitsoeng.