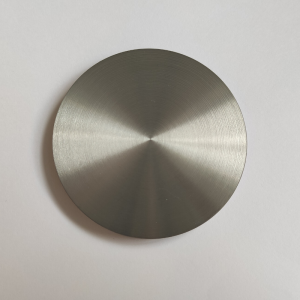

TiAl Sputtering Target High Purity Thin Film Pvd Coating Custom Made

Aluminium ea Titanium

Video

Tlhaloso ea Sepheo sa Titanium Aluminium Sputtering

Tlhokahalo ea boleng bo reriloeng bakeng sa ho roala sputter e phahame ho feta ea indasteri ea thepa ea setso. Sebopeho sa microstructure se ts'oanang sa sepheo se ama ka ho toba ts'ebetso ea sputtering. Re na le sistimi e phethiloeng ea taolo ea boleng mme re khetha lisebelisoa tse tala tse hloekileng ebe re li kopanya ka botlalo ho netefatsa homogeneity. Titanium Aluminium alloy sputtering target e hlahisoa ka mokhoa oa vacuum hot press.

Lipheo tsa rona tsa Titanium Aluminium sputtering li ka fana ka tšireletso ea nitride e hanyetsanang le oxidation, Titanium aluminium nitride (TiAlN). TiAlN ke eona e hlahelletseng hajoale e le filimi ea ho seha lisebelisoa, likarolo tse thellang le li-tribo-coatings. E na le boima bo phahameng, boima, ts'ebetso e sa sebetseng hantle le mocheso oa oxidation.

Lipheo tsa rona tse tloaelehileng tsa TiAl le thepa ea tsona

| Ti-75Al at% | Ti-70Al at% | Ti-67Al at% | Ti-60Al at% | Ti-50Al at% | Ti-30Al at% | Ti-20Al at% | Ti-14Al at% | |

| Bohloeki (%) | 99.7 | 99.7 | 99.7 | 99.7 | 99.8/99.9 | 99.9 | 99.9 | 99.9 |

| Botenya(g/cm3) | 3.1 | 3.2 | 3.3 | 3.4 | 3.63/3.85 | 3.97 | 4.25 | 4.3 |

| Gpula Boholo(µm) | 100 | 100 | 100 | 100 | 100/- | - | - | - |

| Tshebetso | HIP | HIP | HIP | HIP | HIP/VAR | VAR | VAR | VAR |

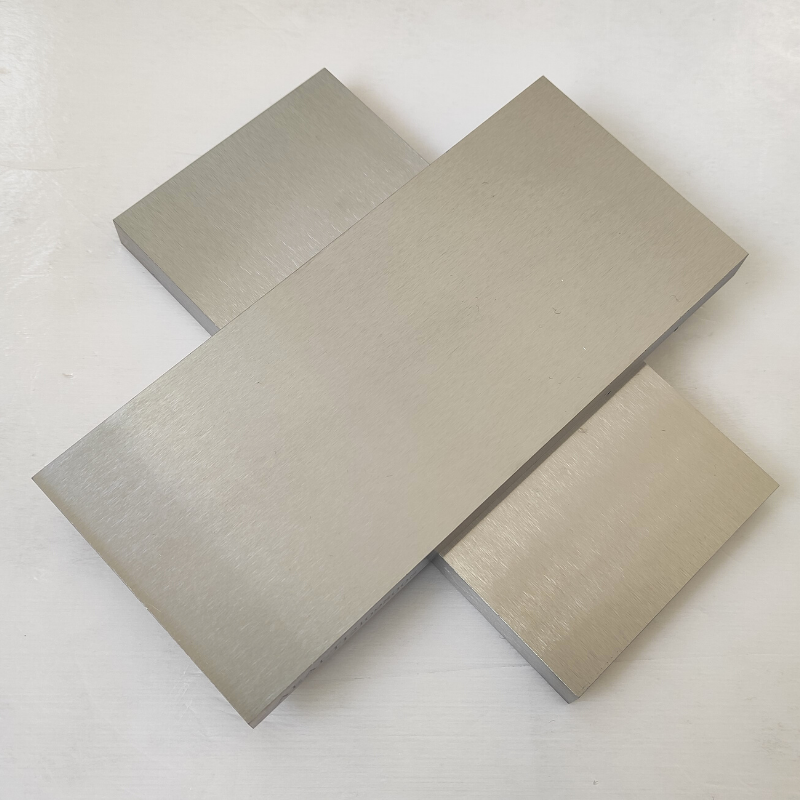

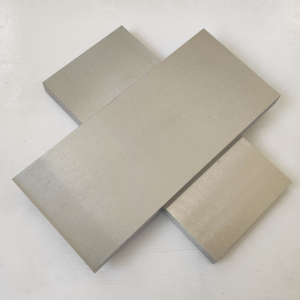

Titanium Aluminium Sputtering Target Packaging

Sepheo sa rona sa Titanium Aluminium sputter se tšoailoe ka ho hlaka le ho ngoloa ka ntle ho netefatsa boitsebiso bo nepahetseng le taolo ea boleng. Ho hlokomeloa haholo ho qoba tšenyo leha e le efe e ka bakoang nakong ea polokelo kapa ea lipalangoang.

Fumana Lebitso

Lipheo tsa RSM's Titanium Aluminium sputtering targets ke tsa bohloeki bo phahameng haholo le junifomo. Li fumaneha ka mefuta e fapaneng, purities, boholo le litheko.

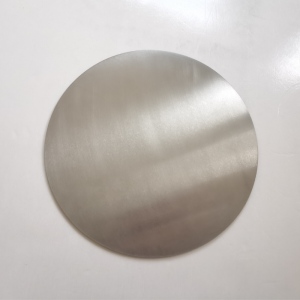

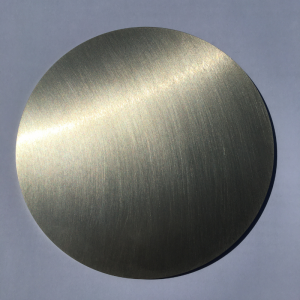

Re ne re ka fana ka mefuta e fapaneng ea libopeho tsa geometri: li-tubes, arc cathodes, planar kapa tloaelo e entsoeng, le mefuta e mengata ea Aluminium. Lihlahisoa tsa rona li na le lisebelisoa tse ntle haholo tsa mochini, sebopeho sa homogeneous microstructure, sebaka se bentšitsoeng se se nang karohano, li-pores kapa mapetsong.

Re sebetsa ka ho khetheha ho hlahiseng lisebelisoa tsa ho roala filimi tse hloekileng tse tšesaane tse nang le ts'ebetso e ntle ka ho fetesisa hammoho le boholo bo phahameng ka ho fetesisa ba lijo-thollo tse ka sebelisoang ho roala hlobo, mokhabiso, likarolo tsa koloi, khalase e tlase-E, potoloho e kopaneng ea semi-conductor, filimi e tšesaane. ho hanyetsa, ponts'o ea litšoantšo, sebaka sa sefofane, ho rekota ka matla a khoheli, skrine ea ho ama, betri ea letsatsi e tšesaane ea filimi le lits'ebetso tse ling tsa 'mele tsa ho beha mouoane (PVD). Ka kopo re romelle potso mabapi le litheko tsa hajoale mabapi le lipehelo tsa sputtering le lisebelisoa tse ling tsa deposition tse sa thathamisitsoeng.