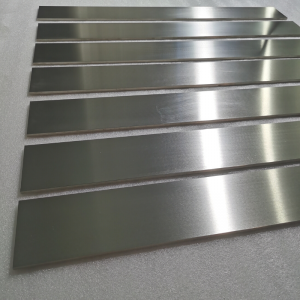

NiFe Sputtering Target High Purity Thin Film Pvd Coating Custom Made

Tšepe ea Nickel

Video

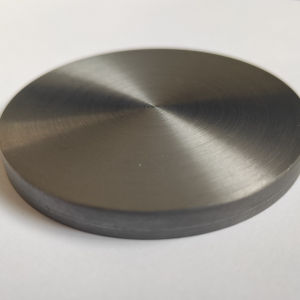

Nickel Iron Sputtering Target Tlhaloso

Nickel Iron Sputtering Target e etsoa ka Vacuum Melting, Casting le PM. E na le matla a matla a khoheli a phahameng haholo ka matla a tlase a tšimo.

Chelete ea tšepe ea nickel (Nickel>30 wt%) e bonts'a sebopeho sa cubic e bohareng ba sefahleho mocheso oa kamore. Lipehelo tsa Nickel Iron li na le ho feta 36% ea sebopeho sa Nickel, 'me li ka aroloa ka mekhahlelo e mene: 35% ~40% Ni-Fe, 45% ~50% Ni-Fe, 50%~65% Ni-Fe le 70% ~81% Ni-Fe. E 'ngoe le e' ngoe e ne e ka etsoa lisebelisoa tse nang le selika-likoe, likhutlo li tharo kapa sefofane sa magnetic hysteresis loops.

Nickel Iron (Ni-Fe) Sputtering Targets e sebelisoa mefuteng e mengata ea lits'ebetso, mohlala, mecha ea litaba ea polokelo ea makenete le lisebelisoa tse sireletsang EMI.

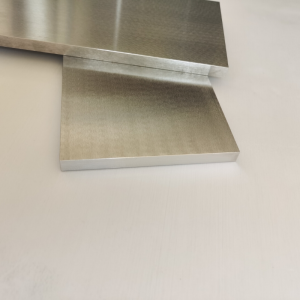

Nickel Iron Sputtering Target Packaging

Sepheo sa rona sa Nickel Iron sputter se tšoailoe ka ho hlaka le ho ngoloa ka ntle ho netefatsa boitsebiso bo nepahetseng le taolo ea boleng. Ho hlokomeloa haholo ho qoba tšenyo leha e le efe e ka bakoang nakong ea polokelo kapa ea lipalangoang.

Fumana Lebitso

RSM's Nickel Iron sputtering targets ke tsa bohloeki bo phahameng haholo le junifomo. Li fumaneha ka mefuta e fapaneng, purities, boholo le litheko. Re ka fana ka bohloeki 99.99% le lipina tsa rona tse tloaelehileng: Ni-Fe10at%、N-iFe16at%, Ni-Fe19at%, Ni-Fe20at%, Ni-Fe36at%, Ni-Fe50at%, Ni-Fe70at%.

Re sebetsa ka ho khetheha ho hlahiseng lisebelisoa tsa ho roala filimi tse hloekileng tse tšesaane tse nang le ts'ebetso e ntle ka ho fetesisa hammoho le boholo bo phahameng ka ho fetesisa ba lijo-thollo tse ka sebelisoang ho roala hlobo, mokhabiso, likarolo tsa koloi, khalase e tlase-E, potoloho e kopaneng ea semi-conductor, filimi e tšesaane. ho hanyetsa, ponts'o ea litšoantšo, sebaka sa sefofane, ho rekota ka matla a khoheli, skrine ea ho ama, betri ea letsatsi e tšesaane ea filimi le lits'ebetso tse ling tsa 'mele tsa ho beha mouoane (PVD). Ka kopo re romelle potso mabapi le litheko tsa hajoale mabapi le lipehelo tsa sputtering le lisebelisoa tse ling tsa deposition tse sa thathamisitsoeng.