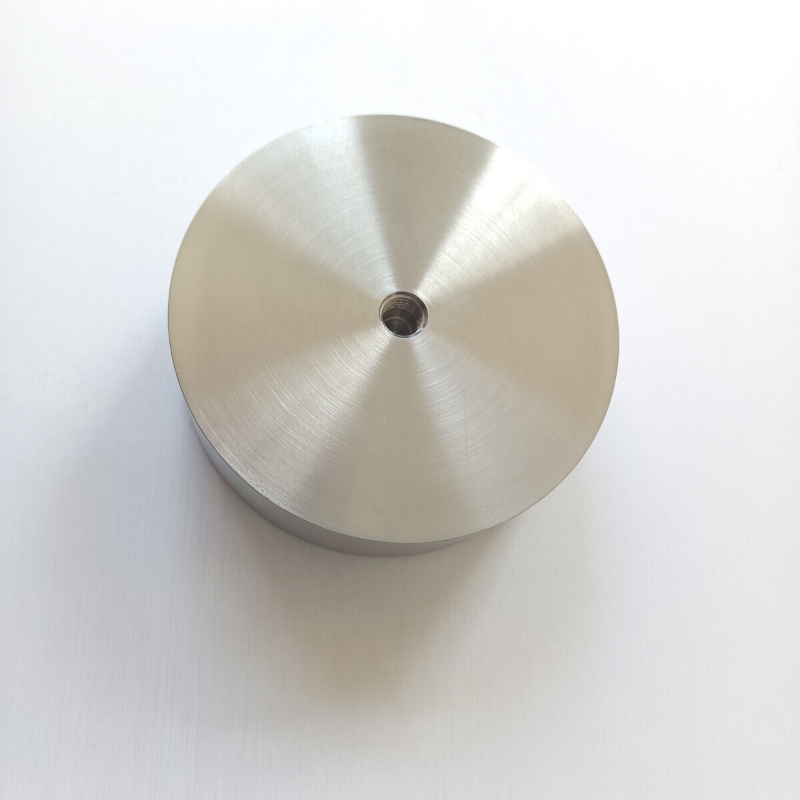

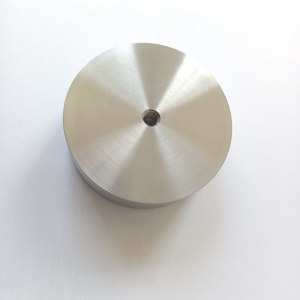

NiCrAlY Sputtering Target High Purity Thin Film Pvd Coating Custom Made

Nickel Chromium Aluminium Yttrium

Video

Nickel Chromium Aluminium Yttrium Sputtering Target Tlhaloso

Sepheo sa NiCrAlY Sputtering se hlahisoa ke Vacuum Melting ea lisebelisoa tse tala tsa Nickel Chromium Aluminium Yttrium. E na le botsitso bo phahameng le boholo bo botle ba lijo-thollo mme ha e na li-pores. Sebopeho sa eona sa Chromium se tloha ho 10-30% (wt), Aluminium 10-20% (wt), Yttrium 0.5-1.0% (wt), 'me e hlahisa sebopeho se nang le mahlakore a mabeli sa γ + β.

NiCrAlY layer hangata e sebelisoa e le liphahlo tse thibelang mocheso. Mocheso o phahameng oa mocheso o bolela tlhaselo ea lik'hemik'hale ea Chromia-forming Iron, Nickel le Cobalt-base Alloys ho tloha likhase, letsoai le tiileng kapa le qhibilihisitsoeng, kapa litšepe tse qhibilihisitsoeng, hangata mochesong o ka holimo ho 400°C (750ºF). Tšebeliso ea lera la NiCrAlY le sebelisitsoeng ho High Temperature Step Alloy ea lifofane le turbine ea khase e ka ntlafatsa ts'ebetso e thibelang kutu le ho lelefatsa bophelo ba sehlahisoa.

Nickel Chromium Aluminium Yttrium Sputtering Target Packaging

Ea rona Nickel Chromium Aluminium Yttriumsputter targete tšoailoe ka ho hlaka le ho ngoloa ka ntle ho netefatsa boitsebiso bo sebetsang hantle le taolo ea boleng. Ho hlokomeloa haholo ho qoba tšenyo leha e le efe e ka bakoang nakong ea polokelo kapa ea lipalangoang.

Fumana Lebitso

RSM's Nickel Chromium Aluminium Yttrium sputtering targets ke tsa bohloeki bo phahameng haholo le junifomo. Li fumaneha ka mefuta e fapaneng, purities, boholo le litheko. Re sebetsa ka ho khetheha ho hlahiseng lisebelisoa tsa ho roala filimi tse hloekileng tse tšesaane tse nang le ts'ebetso e ntle ka ho fetesisa hammoho le boholo bo phahameng ka ho fetesisa ba lijo-thollo tse ka sebelisoang ho roala hlobo, mokhabiso, likarolo tsa koloi, khalase e tlase-E, potoloho e kopaneng ea semi-conductor, filimi e tšesaane. ho hanyetsa, ponts'o ea litšoantšo, sebaka sa sefofane, ho rekota ka matla a khoheli, skrine ea ho ama, betri ea letsatsi e tšesaane ea filimi le lits'ebetso tse ling tsa 'mele tsa ho beha mouoane (PVD). Ka kopo re romelle potso mabapi le litheko tsa hajoale mabapi le lipehelo tsa sputtering le lisebelisoa tse ling tsa deposition tse sa thathamisitsoeng.