Pele, bareki ba bangata ba ile ba botsa basebetsi-'moho le bona ho tsoa Lefapheng la Theknoloji la RSM mabapi le alloy ea titanium. Joale, ke kopa ho akaretsa lintlha tse latelang mabapi le hore na tšepe ea titanium e entsoe ka eng. Ke tšepa ba ka u thusa.

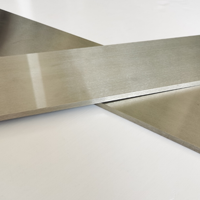

Titanium alloy ke motsoako o entsoeng ka titanium le likarolo tse ling.

Titanium ke kristale ea homogeneous heterogeneous, e nang le ntlha e qhibilihang ea 1720 ℃. Ha mocheso o le ka tlase ho 882 ℃, e na le mohaho o haufi-ufi oa hexagonal lattice, o bitsoang α Titanium; E na le sebopeho sa 'mele sa cubic ka holimo ho 882 ℃, se bitsoang β Titanium. Ho nka monyetla ka litšoaneleho tse fapaneng tsa meaho e 'meli e kaholimo ea titanium, likarolo tse loketseng tsa alloy li eketsoa ho fetola butle-butle mocheso oa phetoho ea mokhahlelo le dikahare tsa mokhahlelo ho fumana li-alloys tsa titanium tse nang le meaho e fapaneng. Mocheso oa kamore, metsoako ea titanium e na le mefuta e meraro ea mekhoa ea matrix, 'me metsoako ea titanium le eona e arotsoe ka mekhahlelo e meraro e latelang: α Alloy(α+β) Alloy le β Alloy. Chaena, e bontšoa ke TA, TC le TB ka ho latellana.

α titanium motsoako

Ke α Single phase alloy e entsoeng ka mohato o tiileng oa tharollo ke α Phase, sebopeho se tsitsitseng, khanyetso e phahameng ea ho apara ho feta titanium e hloekileng, khanyetso e matla ea oxidation. Tlas'a mocheso oa 500 ℃ ~ 600 ℃, e ntse e boloka matla a eona le ho hanyetsa ha metsi, empa e ke ke ea matlafatsoa ke phekolo ea mocheso, 'me matla a eona a mocheso oa kamoreng ha a phahame.

β motsoako oa titanium

Ke β Alloy ea karolo e le 'ngoe e entsoeng ka tharollo e tiileng ea mohato e na le matla a holimo ntle le phekolo ea mocheso. Ka mor'a ho tima le ho tsofala, motsoako o matlafatsoa ka ho eketsehileng, 'me matla a mocheso oa kamore a ka fihla ho 1372 ~ 1666 MPa; Leha ho le joalo, botsitso ba mocheso bo futsanehile 'me ha bo loketse ho sebelisoa mocheso o phahameng.

α+β motsoako oa titanium

Ke motsoako oa mekhahlelo e 'meli e nang le thepa e ntle e felletseng, botsitso bo botle ba sebopeho, ho tiea ho hotle, polasetiki le thepa ea deformation e phahameng ea mocheso. E ka sebelisoa bakeng sa ts'ebetso ea khatello e chesang, ho tima le ho tsofala ho matlafatsa motsoako. Matla ka mor'a phekolo ea mocheso ke hoo e ka bang 50% ~ 100% e phahameng ho feta ka mor'a hore annealing; Matla a mocheso o phahameng, a ka sebetsa ho 400 ℃ ~ 500 ℃ nako e telele, 'me botsitso ba eona ba mocheso bo ka tlaase ho α Titanium alloy.

Har'a li-alloys tse tharo tsa titanium α Titanium alloys le α + β Titanium alloy; α Titanium alloy e na le machinability ka ho fetisisa, α+ P Titanium alloy e nka sebaka sa bobeli, β Titanium alloy e futsanehile. α Khoutu ea titanium alloy ke TA, β Khoutu ea titanium alloy ke TB, α+β Khoutu ea titanium alloy ke TC.

Li-alloys tsa titanium li ka aroloa ka li-alloys tse thibelang mocheso, li-alloys tse matla haholo, li-alloys tse thibelang kutu (titanium molybdenum, titanium palladium alloys, joalo-joalo), li-alloys tse nang le mocheso o tlaase le lisebelisoa tse khethehileng tse sebetsang (lisebelisoa tsa polokelo ea titanium iron hydrogen le li-alloys tsa memori ea titanium nickel). ) ho latela likopo tsa bona.

Phekolo ea mocheso: alloy ea titanium e ka fumana sebopeho le sebopeho sa mekhahlelo e fapaneng ka ho fetola ts'ebetso ea kalafo ea mocheso. Ka kakaretso ho lumeloa hore equiaxed microstructure e ntle e na le polasetiki e ntle, botsitso ba mocheso le matla a mokhathala; Sebopeho sa acicular se na le matla a phahameng a ho phunyeha, matla a ho hahaba le ho thatafala ha fracture; Li-tissue tse kopaneng tse equiaxed le acicular li na le mesebetsi e mengata e felletseng

Nako ea poso: Oct-26-2022