Kaofela rea tseba hore sputtering ke e 'ngoe ea mahlale a mantlha a ho lokisa thepa ea lifilimi. E sebelisa li-ion tse hlahisoang ke mohloli oa ion ho potlakisa aggregation ka har'a vacuum ho theha leballo la ion le lebelo le phahameng, ho qhomisa bokaholimo bo tiileng, 'me li-ion li fapanyetsana matla a kinetic le liathomo tse holim'a metsi a tiileng, e le hore liathomo tse holim'a sebaka se tiileng. bokaholimo bo tloha bo tiileng 'me bo behiloe holim'a substrate. Seliba se bomotsoeng ke thepa e tala ea ho beha filimi ka ho fafatsa, e bitsoang sputtering target.

Mefuta e fapaneng ea lisebelisoa tsa lifilimi tse sputtered e 'nile ea sebelisoa haholo lipotolohong tse kopantsoeng tsa semiconductor, mecha ea phatlalatso ea ho rekota, ponts'o ea planar, lisebelisoa le ho roala holim'a metsi joalo-joalo.

Lipheo tsa sputtering li sebelisoa haholo indastering ea elektroniki le ea tlhahisoleseling, joalo ka li-circuits tse kopaneng, polokelo ea tlhahisoleseling, lipontšo tsa kristale ea metsi, mehopolo ea laser, lisebelisoa tsa taolo ea elektroniki, joalo-joalo; E ka boela ea sebelisoa tšimong ea ho roala khalase; E ka boela ea sebelisoa ka thepa e sa senyeheng, ho hanyetsa mocheso o phahameng oa mocheso, lihlahisoa tse khabisitsoeng tse phahameng le liindasteri tse ling.

Ho na le mefuta e mengata ea lipehelo tsa sputtering, 'me ho na le mekhoa e fapaneng ea ho arola lipehelo:

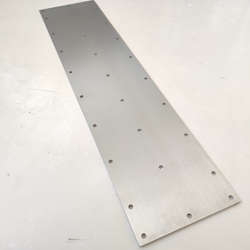

Ho ea ka sebopeho, e ka aroloa ka sepheo sa tšepe, sepheo sa alloy le sepheo sa metsoako ea ceramic.

Ho ea ka sebōpeho, e ka aroloa ka sepheo se selelele, sepheo sa lisekoere le sepheo se pota-potileng.

E ka aroloa ka sepheo sa microelectronic, target magnetic recording target, optical disk target, tšepe ea bohlokoa ea tšepe, sepheo sa ho hanyetsa filimi, sepheo sa filimi ea conductive, sepheo sa phetoho ea holim'a sefahleho, sepheo sa mask, sepheo sa lera la mekhabiso, sepheo sa electrode le lipheo tse ling ho ea ka tšimo ea kopo.

Ho latela lits'ebetso tse fapaneng, e ka aroloa ka lipheo tsa ceramic tse amanang le semiconductor, ho rekota lipheo tsa ceramic tse mahareng, lipehelo tsa ponts'o ea ceramic, lipheo tsa ceramic tsa superconducting le lipheo tse kholo tsa magnetoresistance ceramic.

Nako ea poso: Jul-29-2022