Li-alloys tse thehiloeng ho silevera le litšepe tse ling. Ho na le mefuta e mengata ea li-alloys tsa silevera, tse bohlokoa ka ho fetisisa tsa tsona ke: li-alloys tsa silevera-copper, li-alloys tsa silevera-magnesium, li-alloys tsa silevera-nickel, li-alloys tsa silevera-tungsten, li-alloys tsa silevera-tšepe le li-alloys tsa silevera-cerium.

Lisebelisoa tsa tšepe tsa bohlokoa tse nang le silevera e le karolo e ka sehloohong. Ka kakaretso sebelisa silevera e hloekileng kapa silevera e hloekileng (99.9 ** * ka holimo) e le lisebelisoa tse tala, e lokela ho qoba bismuth, lead, antimoni le litšila tse ling tse kotsi. Silevera e ka etsoa ka likarolo tse ngata ka tharollo e tiileng, metsoako ea intermetallic kapa karolo e bohareng, hammoho le mefuta e mengata ea lisebelisoa tse kopantsoeng (alloy ea bohata). Ho itšetlehile ka litlhoko, li ka etsoa li-binary, ternary kapa polyalloys. Li-alloys tsa silevera li sebelisoa haholo libakeng tse ngata tsa theknoloji ea indasteri.

Lisebelisoa tse ka sehloohong tsa li-alloys tsa silevera ke:

(1) lisebelisoa tsa tšepe tse entsoeng ka silevera, haholo-holo li-alloys tsa silevera-copper-zinc e le motheo oa ho hlophisoa ha lihlopha tsa alloy, tse kang tsamaiso ea AgCuZn, tsamaiso ea AgCuZnCd, tsamaiso ea AgCuZnNi; silevera-nickel alloy, silevera-copper alloy;

E na le 90% ea silevera le 10% alloy ea koporo e bitsoang currency silver, melting point 875 ℃; e nang le silevera ea 80% le motsoako oa koporo oa 20% o bitsoang silevera ea mosebetsi o motle, ntlha ea ho qhibiliha 814 ℃; e nang le 40% kapa 60% silevera le koporo, zinki, li-alloys tsa cadmium tse bitsoang silver solder, ntlha ea ho qhibiliha e kholo ho feta 600 ℃. Haholo-holo e sebelisetsoang ho hokahanya litlhoko tse phahameng tsa matla a lihlahisoa tsa tšepe.

(2) lisebelisoa tse amanang le silevera, haholo-holo alloy ea silevera-copper (AgCu3, AgCu7.5), le silver-cadmium oxide alloy le silver-nickel alloy;

(3) lisebelisoa tsa ho hanyetsa tse thehiloeng silevera, silevera ea manganese tin alloy resistance coefficient e leka-lekaneng, mocheso oa ho hanyetsa mocheso o tlaase, matla a koporo a mocheso a nyenyane, a ka sebelisoa e le lisebelisoa tse tloaelehileng tsa ho hanyetsa le potentiometer; silevera molybdenum alloy, silevera tungsten alloy, silevera ferroalloy, silevera cadmium alloy;

(4) lisebelisoa tse entsoeng ka silevera, tse sebelisoang ka tloaelo silevera-tin alloy AgSn3 ~ 5, AgPb0.4 ~ 0.7, AgPd3 ~ 5 joalo-joalo;

(5) lisebelisoa tsa meno tse thehiloeng ka silevera, amalgam ea silevera, e tsejoang hape e le amalgam, ke mercury e le solvent, silver-copper-tin-zinc e le alloy powder, karabelo e etsahala ka ho sila le ho thehoa ha mofuta oa motsoako, ke lisebelisoa tse ntle tsa veneer. Silver amalgam AgxHg, bosoeu bo sa leka-lekaneng bo tiileng. Sebopeho sa eona se fapana ho itšetlehile ka mocheso oa sebopeho; Ag13Hg (445°C), Ag11Hg (357°C), Ag4Hg (302°C), AgHg2 (tlase ho 300°C)

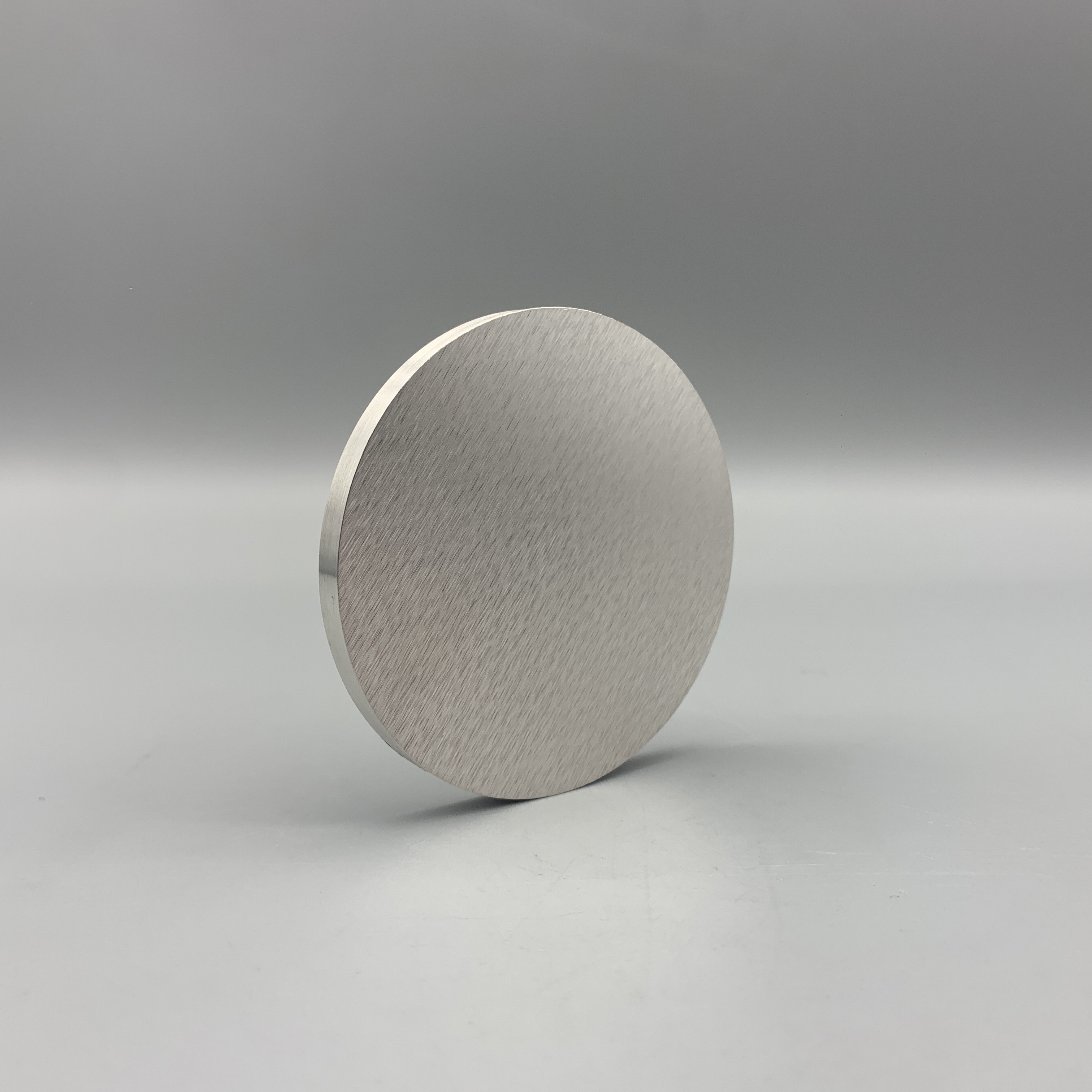

Thepa ea alloy ea silevera e ntlafala.

Silevera e bonolo haholo ebile e bonolo ho sebetsa. E le ho ntlafatsa matla a eona le boima ba eona le ho eketsa ho hanyetsa ha eona, khale batho ba ile ba eketsa koporo ho silevera ho etsa li-alloys tsa silevera-koporo, tse sebelisoang ka mabenyane, tableware le lichelete tsa tšepe tsa silevera. E le ho ntlafatsa ts'ebetso ea alloy ea silevera ea koporo, hangata eketsa nickel, beryllium, vanadium, lithium le sehlopha se seng sa boraro sa likarolo ho li-alloys tsa ternary. Ho phaella moo, ho na le lintho tse ling tse ngata tse kenyelletsoeng silevera le tsona li ka phetha karolo ea ho matlafatsa.

Leha ho le joalo silevera e inert sepakapakeng organic, empa ho bonolo ho ba sebabole-e nang le sepakapaka corrosion le sulfide. Ntlafatso ea khanyetso ea silevera ea sulfide e boetse e sebelisoa ka mokhoa oa ho kopanya, joalo ka ho eketsoa ha khauta le palladium ho ka fokotsa sekhahla sa tlhahiso ea filimi ea silevera ea sulfide. Ho feta moo, lisebelisoa tse ngata tsa tšepe tse kang manganese, antimony, tin, germanium, arsenic, gallium, indium, aluminium, zinki, nickel, vanadium ka har'a silevera le tsona li ka ntlafatsa thepa ea eona ea anti-sulfuration. Lisebelisoa tsa motlakase tse thehiloeng ho silevera li na le mefuta e mengata, ho na le boemo ba alloy, ho boetse ho sebelisoa mekhoa ea metallurgy ea phofo e entsoeng ka alloy ea bohata, sepheo ke ho matlafatsa, ho se sebetse le ho ntlafatsa thepa ea motlakase.

E fetoletsoe ka DeepL.com (mofuta oa mahala)

Nako ea poso: Mar-07-2024