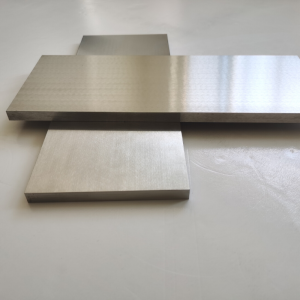

AlSi Alloy Sputtering Target High Purity Thin Film PVD Coating Custom Made

Aluminium Silicon

Aluminium Silicon Sputtering Target Tlhaloso

Lipheo li lokisoa ka ho kopanya Aluminium le Silicon powders tse lateloang ke compaction ho fihlela boima bo feletseng. Thepa e hahelletsoeng ka tsela e joalo e sireloa ka boikhethelo ebe e etsoa sebopeho se batloang. Lipheo tsa rona tsa Aluminium Silicon sputtering li fumaneha ka liforomo tsa li-geometric tse khutlonnetsepa, selikalikoe kapa tse entsoeng ka mokhoa o ikhethileng, dikahare tsa Aluminium ho tloha ho 10-90% ea athomo, 'me li na le bohloeki bo phahameng, sebopeho sa homogeneous, bongata bo phahameng le bophelo bo bolelele ba ho sebetsa.

Aluminium Silicon e sebelisoa haholo indastering ea likoloi, lifofane le kaho bakeng sa motsoako oa eona o ikhethang oa litšobotsi tse lakatsehang, ho kenyelletsa boima bo bobebe , conductivity e ntle ea mocheso le thepa ea mechine. Boima ba thepa ena ke 2.6 ~ 2.7g / cm3, mocheso conductivity coefficient 101 ~ 126W / (m · ℃), tensile modulus 71.0GPa, mokhathala moeli ± 45MPa. Li-alloys tsa aluminium-silicon li boetse li na le khanyetso e ntle ea kutu, machinability, le weldability. Li-alloys tsa aluminium-silicon li sebelisoa mefuteng e fapaneng ea lisebelisoa tsa likoloi, sefofane, le lihlahisoa tsa bareki, joalo ka li-block blocks le li-cylinder liner, li-pistons, li-bearing alloy materials, le lisebelisoa tsa motlakase tsa bareki. E na le ntlha e phahameng ea ho qhibiliha, ductility, thata, le ho hanyetsa ho bola.

Aluminium Silicon Sputtering Target Packaging

Sepheo sa rona sa Aluminium Silicon sputter se tšoailoe ka ho hlaka le ho ngoloa ka ntle ho netefatsa boitsebiso bo nepahetseng le taolo ea boleng. Ho hlokomeloa haholo ho qoba tšenyo leha e le efe e ka bakoang nakong ea polokelo kapa ea lipalangoang.

Fumana Lebitso

RSM's Aluminium Silicon sputtering targets ke tsa bohloeki bo phahameng haholo le junifomo. Li fumaneha ka mefuta e fapaneng, purities, boholo le litheko. Re sebetsa ka ho khetheha ho hlahiseng lisebelisoa tsa ho roala filimi tse hloekileng tse tšesaane tse nang le ts'ebetso e ntle ka ho fetesisa hammoho le boholo bo phahameng ka ho fetesisa ba lijo-thollo tse ka sebelisoang ho roala hlobo, mokhabiso, likarolo tsa koloi, khalase e tlase-E, potoloho e kopaneng ea semi-conductor, filimi e tšesaane. ho hanyetsa, ponts'o ea litšoantšo, sebaka sa sefofane, ho rekota ka matla a khoheli, skrine ea ho ama, betri ea letsatsi e tšesaane ea filimi le lits'ebetso tse ling tsa 'mele tsa ho beha mouoane (PVD). Ka kopo re romelle potso mabapi le litheko tsa hajoale mabapi le lipehelo tsa sputtering le lisebelisoa tse ling tsa deposition tse sa thathamisitsoeng.