Alloys ku salaysan lacag iyo biraha kale. Waxaa jira noocyo badan oo ah alwaaxyo qalin ah, kuwaas oo ay ugu muhiimsan yihiin: Alloys silver-copper, silver-magnesium alloys, silver-nickel alloys, silver-tungsten alloys, silver-iron alloys iyo silver-cerium alloys.

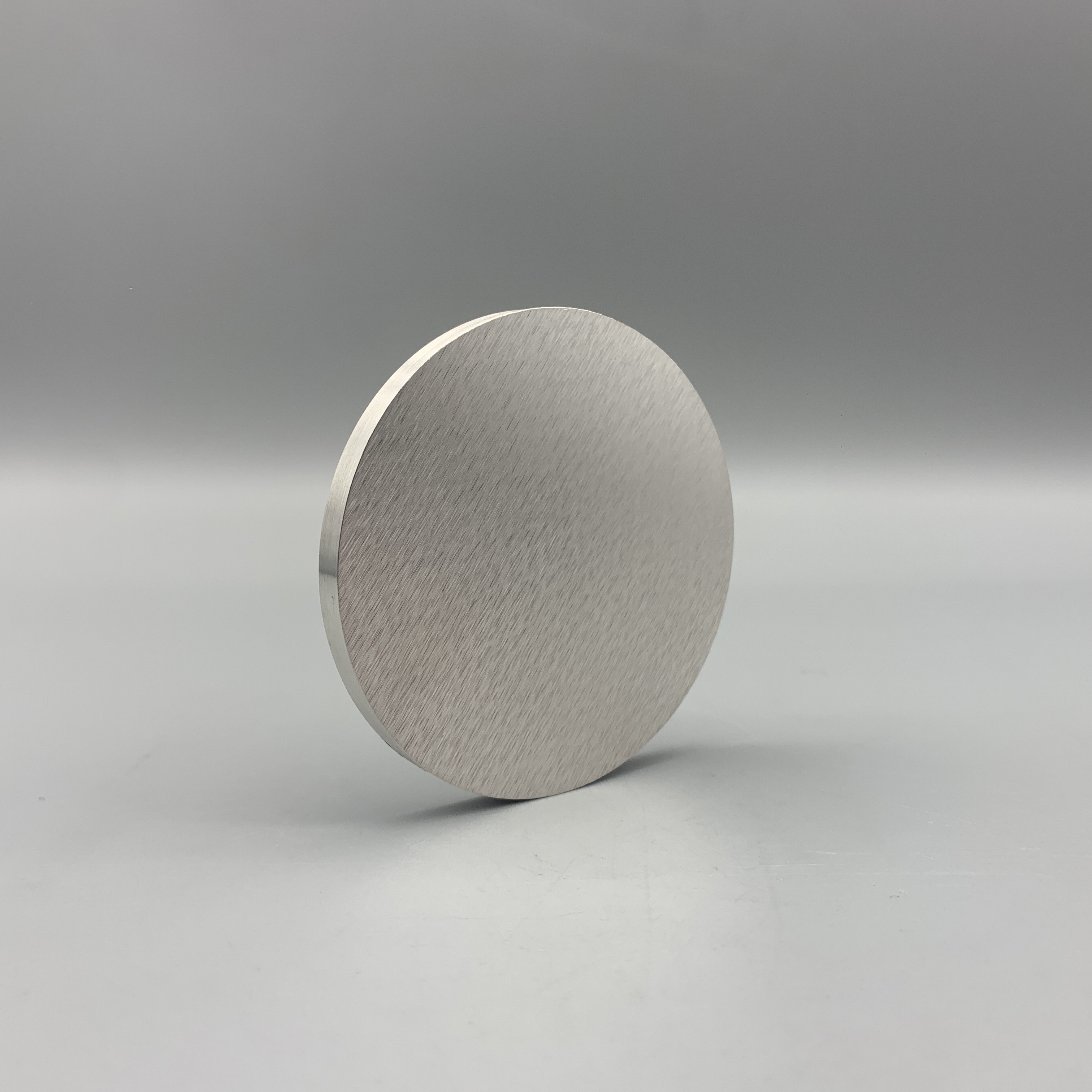

Qalab bir ah oo qaali ah oo lacag ah sida qaybta ugu muhiimsan. Guud ahaan u isticmaal qalin saafi ah ama lacag saafi ah (99.9*** sare) alaab cayriin ah, waa in aad ka fogaato bismuth, rasaas, antimony iyo wasakh kale oo waxyeelo leh. Silver waxaa lagu samayn karaa walxo badan oo xal adag ah, isku-dhafka birta ah ama marxaladda dhexdhexaadka ah, iyo sidoo kale noocyo badan oo ah walxaha isku dhafan (daawaha beenta ah). Iyadoo ku xiran baahida, waxaa laga dhigi karaa binary, ternary ama polyalloys. Alloys Silver waxaa si weyn loogu isticmaalaa meelo badan oo technology warshadaha.

Codsiyada ugu muhiimsan ee alloys silver waa:

(1) Walxaha naxaasta ku salaysan ee qalinka ah, oo u badan silver-copper-zinc alloys oo saldhig u ah halabuurka taxanaha alloy, sida nidaamka AgCuZn, nidaamka AgCuZnCd, nidaamka AgCuZnNi; daawaha silver-nickel, daawaha silver-naxaas;

Ka kooban 90% qalin iyo 10% naxaas daawaha ah oo loo yaqaan lacagta lacagta, barta dhalaalka 875 ℃; oo ka kooban 80% qalin iyo 20% naxaas daawaha ah oo loo yaqaan qalin shaqo fiican, barta dhalaalka 814 ℃; oo ka kooban 40% ama 60% qalin iyo naxaas, zinc, alloys cadmium oo loo yaqaan alxanka qalinka, barta dhalaalka oo ka weyn 600 ℃. Inta badan loo isticmaalo in lagu xidho shuruudaha xoogga sare ee alaabta birta.

(2) Walxaha xidhiidhka ee ku salaysan qalinka, oo u badan alloy silver-copper (AgCu3, AgCu7.5)

(3) Walxaha iska caabinta lacag-ku-saleysan, manganese qalinka daasadaha caabbinta iska caabbinta waa dhexdhexaad, heerkulka iska caabintu waa mid hooseeya, awoodda kulaylka naxaasta waa yar yahay, waxaa loo isticmaali karaa caabiyaha caadiga ah iyo qalabka dabaysha potentiometer; daawaha lacagta molybdenum, aluminium tungsten silver, ferroalloy silver, cadmium alloy lacag;

(4) Alaabaha dahaadhan qalin ku salaysan, oo caadi ahaan loo isticmaalo aluminium silver-tin alloy AgSn3 ~ 5, AgPb0.4 ~ 0.7, AgPd3 ~ 5 iyo wixii la mid ah;

(5) Qalabka ilkaha ku salaysan lacag, amalgam silver, sidoo kale loo yaqaan amalgam, waa meerkuri sida dareere ah, silver-copper-tin-zinc sida budada daawaha ah, falcelinta waxay dhacdaa iyada oo la shiidi karo iyo samaynta nooc ka mid ah daawaha. waa qalabka ugu habboon ee veneer. Amalgam Silver AgxHg, cad oo aan sinnayn oo adag. Halabuurkeedu wuu kala duwan yahay iyadoo ku xidhan heerkulka samaynta; Ag13Hg (445°C), Ag11Hg (357°C), Ag4Hg (302°C), AgHg2 (in ka yar 300°C)

Guryaha daawaha qalinka ah ayaa horumaraya.

Silver waa mid aad u jilicsan oo sahlan in la shaqeeyo. Si ay u wanaajiso xoogeeda iyo adayggeeda oo ay u kordhiso caabbinta xidhashada, waa hore dadku waxay ku dari jireen naxaasta lacagta si ay u sameeyaan alwaaxyo silver-copper ah, kuwaas oo loo isticmaalo dahabka, alaabta miiska iyo lacagta qalinka ah. Si loo hagaajiyo waxqabadka daawaha silver-naxaasta ah, inta badan ku dar nikkel, beryllium, vanadium, lithium iyo kooxda kale ee saddexaad ee xubno ka mid ah Alloys ternary. Intaa waxaa dheer, waxaa jira walxo kale oo badan oo lagu daray lacagta ayaa sidoo kale door ka ciyaari kara xoojinta.

In kasta oo ay lacagtu ku jirto jawiga dabiiciga ah, laakiin way fududahay in ay noqoto daxal iyo sulfide ka kooban baaruud. Hagaajinta caabbinta sulfide qalinka ah ayaa sidoo kale loo maraa habka alloying, sida ku darida dahabka iyo palladium waxay yareyn kartaa heerka jiilka filimka sulfide silver. Intaa waxaa dheer, walxo badan oo bir ah sida manganese, antimony, tiin, germanium, arsenic, gallium, indium, aluminium, zinc, nickel, vanadium galay lacagta ayaa sidoo kale hagaajin kara sifooyinka anti-sulfuration. Qalabka korantada ee lacag-ku-saleysan waa noocyo badan, waxaa jira xaalad dawac ah, waxaa sidoo kale loo isticmaalaa hababka birta budada ah ee ka samaysan daawaha beenta ah, ujeedadu waa in la xoojiyo, xirto u adkaysta iyo hagaajinta sifooyinka korantada.

Waxaa lagu turjumay DeepL.com (nooca bilaashka ah)

Waqtiga boostada: Mar-07-2024