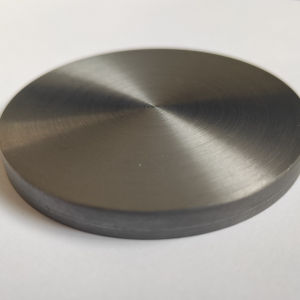

TiSi Sputtering Target High Purity Thin Film Pvd Coating Custom Made

Titanium Silicon

Vhidhiyo

Titanium Silicon Sputtering Target Tsananguro

A super-hard Nitride coating inogona kuumbwa kana Titanium Silicon yasanganiswa neNitrogen gasi panguva yekuisa. Iyo Silicon element iripo inovimbisa yakakwira oxidation kuramba maitiro, nepo Titanium - kuoma. Iyo inogona kuratidza yakanakisa kupfeka kuramba chivakwa kunyangwe kune yakanyanya kukwirisa tembiricha. Maturusi ekucheka akaiswa neTiSiN coating akanakira kukurumidza-kumhanya uye kwakaomarara kugaya, kunyanya mukucheka kwakaoma, uye kunogona kubata nemamwe ma super alloys, seNickel neTitanium base alloys.

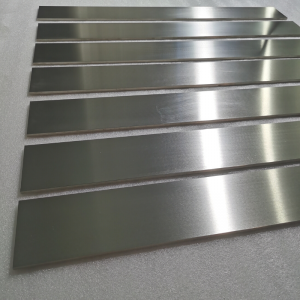

Yedu yakajairika TiSi tarisiro uye zvivakwa zvavo

| Ti-15Sipa% | Ti-20Sipa% | Ti-25Sipa% | Ti-30Sipa% | |

| Kuchena (%) | 99.9 | 99.9 | 99.9 | 99.9 |

| Density(g/cm3) | 4.4 | 4.35 | 4.3 | 4.25 |

| Gmvura Size(µm) | 200/100 | 100 | 100 | 100 |

| Process | VAR/HIP | HIP | HIP | HIP |

Kambani yedu ine makore mazhinji eruzivo rwekugadzira sputtering zvinangwa zvekucheka mold maturusi. Ti-15Si pa%, yakagadzirwa nekunyunguduka kwevacuum, ine homogeneous chimiro, kuchena kwakanyanya uye yakaderera gasi yemukati. Kunze kwezvo, tinopawo Ti-15Si pa%, Ti-20Si pa% uye Ti-25Si pa% inogadzirwa nenzira yesimbi yemagetsi. Zvinangwa zvedu zveTiSi zvine zvakanakisa zvemuchina zvivakwa, zvichiita kuti zvisabatike nekutsemuka uye kutadza kwechimiro.

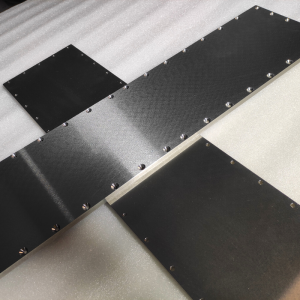

Titanium Silicon Sputtering Target Packaging

Yedu Titanium Silicon sputter tag yakanyorwa zvakajeka uye yakanyorwa kunze kuti ive nechokwadi chekuzivikanwa uye kutonga kwemhando. Kuchenjerera kukuru kunotorwa kudzivirira chero kukuvara kungave kukonzerwa panguva yekuchengetera kana kufambisa.

Wana Contact

RSM's Titanium Silicon sputtering targets ndeyekuchena kwepamusoro-soro uye yunifomu. Iwo anowanikwa mumhando dzakasiyana-siyana, kuchena, saizi, uye mitengo. Isu tine hunyanzvi mukugadzira yakakwira kuchena yakaonda firimu yekupfekedza zvinhu zvine kuita kwakanakisa pamwe nepamusoro-soro dhizaini uye diki inobvira avhareji masaizi ezviyo zvekushandiswa mukuputira mold, kushongedza, zvikamu zvemotokari, girazi rezasi-E, semi-conductor yakabatanidzwa sedunhu, nhete firimu. kuramba, graphic display, aerospace, magineti kurekodha, touch screen, nhete yefirimu solar bhatiri uye mamwe maapplication evapor deposition (PVD). Ndokumbira utitumire kubvunza nezvemitengo yazvino pane sputtering targets nezvimwe zvinhu zvekuisa zvisina kunyorwa.