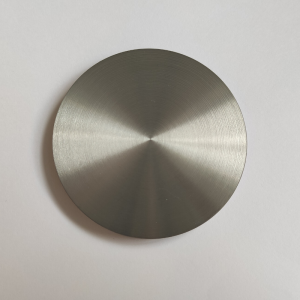

TiAl Sputtering Target High Purity Thin Film Pvd Coating Custom Made

Titanium Aluminium

Vhidhiyo

Titanium Aluminium Sputtering Target Tsananguro

Izvo zvinodikanwa zvemhando yakanangwa ye sputter coating yakakwirira kupfuura iyo yechinyakare zvinhu indasitiri. Iyo yunifomu microstructure yechinangwa inokanganisa zvakananga kuita kwe sputtering. Isu tine yakapedzwa yemhando yekutarisira sisitimu uye isu tinosarudza yakakwirira kuchena zvigadzirwa uye kunyatso sanganisa kuti ive nechokwadi chehomogeneity. Titanium Aluminium alloy sputtering target inogadzirwa nenzira yevacuum inopisa yekutsikirira nzira.

Yedu Titanium Aluminium sputtering targets inogona kupa yakasarudzika oxidation-resistant nitride coating, Titanium aluminium nitride (TiAlN). TiAlN ndiyo yazvino yakakurumbira sefirimu rekucheka maturusi, inotsvedza zvikamu uye tribo-machira. Iyo ine yakanyanya kuoma, kuomarara, kupfeka kusagadzikana kuita uye oxidation tembiricha.

Yedu chaiyo TiAl tarisiro uye zvivakwa zvavo

| Ti-75Al at% | Ti-70Al at% | Ti-67Al at% | Ti-60Al at% | Ti-50Al at% | Ti-30Al at% | Ti-20Al at% | Ti-14Al at% | |

| Kuchena (%) | 99.7 | 99.7 | 99.7 | 99.7 | 99.8/99.9 | 99.9 | 99.9 | 99.9 |

| Density(g/cm3) | 3.1 | 3.2 | 3.3 | 3.4 | 3.63/3.85 | 3.97 | 4.25 | 4.3 |

| Gmvura Size(µm) | 100 | 100 | 100 | 100 | 100/- | - | - | - |

| Process | HIP | HIP | HIP | HIP | HIP/VAR | VAR | VAR | VAR |

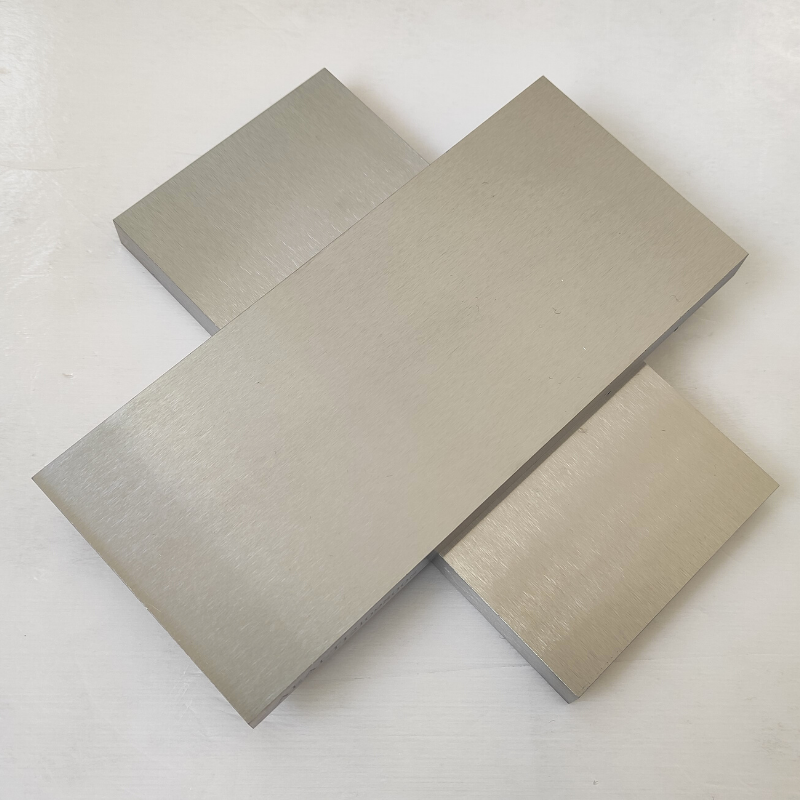

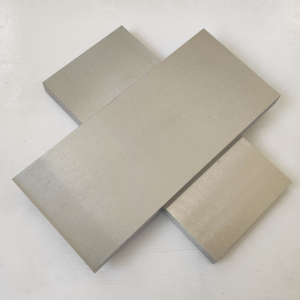

Titanium Aluminium Sputtering Target Packaging

Yedu Titanium Aluminium sputter tag yakanyatso tag uye yakanyorwa kunze kuti ive nechokwadi chekuzivikanwa uye kutonga kwemhando. Kuchenjerera kukuru kunotorwa kudzivirira chero kukuvara kungave kukonzerwa panguva yekuchengetera kana kufambisa.

Wana Contact

RSM's Titanium Aluminium sputtering targets ndeyekuchena kwepamusoro-soro uye yunifomu. Iwo anowanikwa mumhando dzakasiyana-siyana, kuchena, saizi, uye mitengo.

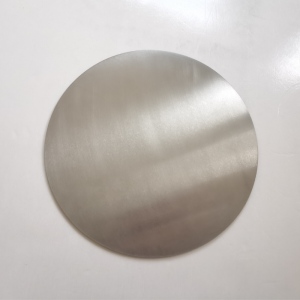

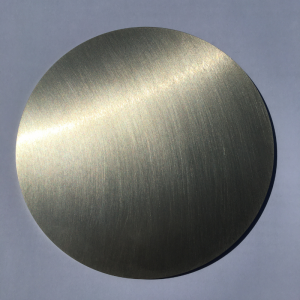

Taigona kupa akasiyana emhando dzejometri: machubhu, arc cathodes, planar kana tsika-yakagadzirwa, uye yakakura chikamu huwandu hweAluminium. Zvigadzirwa zvedu zvinoratidzira zvakanakisa zvemuchina, homogeneous microstructure, yakakwenenzverwa nzvimbo isina kupatsanurwa, pores, kana makatsemuka.

Isu tine hunyanzvi mukugadzira yakakwira kuchena yakaonda firimu yekupfekedza zvinhu zvine kuita kwakanakisa pamwe nepamusoro-soro dhizaini uye diki inobvira avhareji masaizi ezviyo zvekushandiswa mukuputira mold, kushongedza, zvikamu zvemotokari, girazi rezasi-E, semi-conductor yakabatanidzwa sedunhu, nhete firimu. kuramba, graphic display, aerospace, magineti kurekodha, touch screen, nhete yefirimu solar bhatiri uye mamwe maapplication evapor deposition (PVD). Ndokumbira utitumire kubvunza nezvemitengo yazvino pane sputtering targets nezvimwe zvinhu zvekuisa zvisina kunyorwa.