Pamberi, vatengi vazhinji vakabvunza vavanoshanda navo kubva kuRSM Technology Dhipatimendi nezve titanium alloy. Zvino, ndinoda kupfupisa pfungwa dzinotevera kwauri pamusoro pekuti simbi titanium alloy inogadzirwa nei. Ndinovimba vanogona kukubatsira.

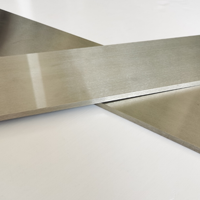

Titanium alloy ialloy yakagadzirwa netitanium nezvimwe zvinhu.

Titanium ikristaro ine homogeneous heterogeneous, ine nzvimbo yekunyungudika ye1720 ℃. Kana tembiricha yadzikira pane 882 ℃, ine yakanyatso kurongedzerwa hexagonal lattice chimiro, iyo inonzi α Titanium; Iine muviri wakatarisana ne cubic chimiro pamusoro pe882 ℃, inodaidzwa kuti β Titanium. Kutora mukana weakasiyana maitiro ezvimiro zviviri zviri pamusoro zvetitanium, yakakodzera alloy zvinhu zvinowedzerwa kuti zvishoma nezvishoma ichinje chikamu chayo chekushandura tembiricha uye chikamu chemukati kuwana titanium alloys ane akasiyana zvimiro. Patembiricha yekamuri, titanium alloys ine marudzi matatu ezvimiro zvematrix, uye titanium alloys akakamurwawo muzvikamu zvitatu zvinotevera: α Alloy( α + β) Alloy uye β Alloy. MuChina, inoratidzwa neTA, TC uye TB zvakateerana.

α titanium alloy

Iyo α Single phase alloy inoumbwa nechikamu chakasimba mhinduro ndeye α Phase, yakagadzikana chimiro, yakakwirira kupfeka kuramba kupfuura yakachena titanium, yakasimba oxidation kuramba. Pasi pekushisa kwe500 ℃ ~ 600 ℃, inoramba ichichengetedza simba rayo uye kusagadzikana kwekamba, asi haigoni kusimbiswa nekurapa kwekupisa, uye simba rekushisa kwekamuri rayo harina kukwirira.

β titanium alloy

Ndiyo β Iyo imwe-chikamu alloy inoumbwa nechikamu chakasimba mhinduro ine simba repamusoro pasina kupisa kupisa. Mushure mekudzima uye kuchembera, iyo alloy inowedzera kusimbiswa, uye tembiricha yekamuri simba rinogona kusvika 1372 ~ 1666 MPa; Zvisinei, kugadzikana kwekushisa kwakashata uye hakukodzeri kushandiswa pakupisa kwakanyanya.

α+β titanium alloy

Iyo iviri chikamu alloy ine yakanaka yakazara zvivakwa, yakanaka kugadzikana kwechimiro, kunaka kusimba, plastiki uye yakakwirira-tembiricha deformation zvivakwa. Inogona kushandiswa pakupisa kudzvinyirira kugadzirisa, kudzima uye kuchembera kusimbisa alloy. The simba pashure kupisa kurapwa anenge 50% ~ 100% yakakwirira kupfuura kuti pashure annealing; Kusimba kwekushisa kwepamusoro, kunogona kushanda pa400 ℃ ~ 500 ℃ kwenguva yakareba, uye kugadzikana kwayo kwekushisa kuduku pane α Titanium alloy.

Pakati pematatu etitanium alloys α Titanium alloys uye α + β Titanium alloy; α Titanium alloy ine yakanakisa machinability, α+ P Titanium alloy inotora nzvimbo yechipiri, β Titanium alloy yakashata. α Kodhi yetitanium alloy ndeye TA, β Kodhi yetitanium alloy is TB, α+β Kodhi yetitanium alloy is TC.

Titanium alloys inogona kupatsanurwa kuita ma alloys anodzivirira kupisa, alloys akasimba-akasimba, corrosion resistant alloys (titanium molybdenum, titanium palladium alloys, nezvimwewo), alloys akadzika-tembiricha uye akakosha anoshanda alloys (titanium iron hydrogen kuchengetedza zvinhu uye titanium nickel memory alloys ) maererano nezvikumbiro zvavo.

Kurapa kwekupisa: titanium alloy inogona kuwana akasiyana chikamu kuumbwa uye chimiro nekugadzirisa kupisa kurapwa maitiro. Zvinowanzotendwa kuti yakanaka equiaxed microstructure ine plastiki yakanaka, kugadzikana kwekupisa uye kuneta simba; Iyo acicular dhizaini ine yakakwirira kuputika simba, inokambaira simba uye kutsemuka kuoma; Mixed equiaxed uye acicular tissues ane zvirinani akazara mabasa

Nguva yekutumira: Oct-26-2022