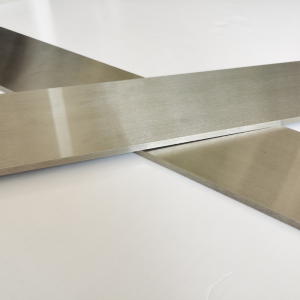

Raw Material High Purity CuSn target Copper-tin alloy magnetron sputtering target copper-tin alloy target

Chromium Cobalt

Raw Material High Purity CuSn target Copper-tin alloy magnetron sputtering target copper-tin alloy target,

CuSn target copper-tin alloy target magnetron sputtering target,

Chromium cobalt sputtering target from Rich Special Materials is a silvery alloy sputtering material containing Cr and Co.

Chromium is a chemical element that originated from the Greek ‘chroma’, meaning color. It was early used before 1 AD and discovered by Terracotta Army. “Cr” is the canonical chemical symbol of chromium. Its atomic number in the periodic table of elements is 24 with a location at Period 4 and Group 6, belonging to the d-block. The relative atomic mass of chromium is 51.9961(6) Dalton, the number in the brackets indicating the uncertainty.

Cobalt is a chemical element that originated from the German word ‘kobald’, meaning goblin. It was first mentioned in 1732 and observed by G. Brandt. “Co” is the canonical chemical symbol of cobalt. Its atomic number in the periodic table of elements is 27 with a location at Period 4 and Group 9, belonging to the d-block. The relative atomic mass of cobalt is 58.933195(5) Dalton, the number in the brackets indicating the uncertainty.

Chronium Cobalt Sputtering Targets are manufactured by means of Vacuum Melting and PM. CrCo has superior specific strength and has been used in various fields where high wear-resistance was needed including aerospace industry, cutlery, bearings, blades, etc.

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Chronium Cobalt Sputtering Materials according to Customers’ specifications. For more information, please contact us.Copper and tin target is made of high purity copper and tin smelting target, copper and tin, also known as bronze, is in pure copper (red copper) added tin or lead alloy, has special importance and historical significance, compared with pure copper (red copper), bronze has high strength and low melting point (25% tin smelting bronze, melting point will be reduced to 800℃. The melting point of pure copper (copper) is 1083℃). Bronze has good casting ability, abrasion resistance and chemical stability. Bronze has low melting point, high hardness, strong plasticity, wear resistance, corrosion resistance, bright color and so on.