Pvd vacuum coating Factory Price Ti-Al50 at% High Purity 99.7% Titanium Aluminum Mental Alloy Sputtering Targets

Chromium Cobalt

Pvd vacuum coating Factory Price Ti-Al50 at% High Purity 99.7% Titanium Aluminum Mental Alloy Sputtering Targets,

,

Chromium cobalt sputtering target from Rich Special Materials is a silvery alloy sputtering material containing Cr and Co.

Chromium is a chemical element that originated from the Greek ‘chroma’, meaning color. It was early used before 1 AD and discovered by Terracotta Army. “Cr” is the canonical chemical symbol of chromium. Its atomic number in the periodic table of elements is 24 with a location at Period 4 and Group 6, belonging to the d-block. The relative atomic mass of chromium is 51.9961(6) Dalton, the number in the brackets indicating the uncertainty.

Cobalt is a chemical element that originated from the German word ‘kobald’, meaning goblin. It was first mentioned in 1732 and observed by G. Brandt. “Co” is the canonical chemical symbol of cobalt. Its atomic number in the periodic table of elements is 27 with a location at Period 4 and Group 9, belonging to the d-block. The relative atomic mass of cobalt is 58.933195(5) Dalton, the number in the brackets indicating the uncertainty.

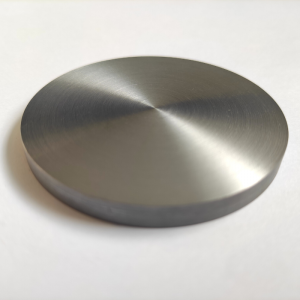

Chronium Cobalt Sputtering Targets are manufactured by means of Vacuum Melting and PM. CrCo has superior specific strength and has been used in various fields where high wear-resistance was needed including aerospace industry, cutlery, bearings, blades, etc.

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Chronium Cobalt Sputtering Materials according to Customers’ specifications. For more information, please contact us.

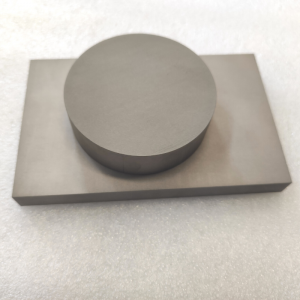

Titanium Aluminum Target

We accept Customized Ratios, Purity and Shape.

Ratios: TiAl5 at%, TiAl10 at%, TiAl20 at%, TiAl25 at%, TiAl 30 at%, TiAl40 at%, TiAl50 at%…

Purity: 99.5%、99.7%、99.8%、99.9%、99.95%、99.99%.

Shape: Circular, Plane, Tube, Arc, Multi-tile…

The requirement of the target quality for sputter coating is higher than that of the traditional materials industry. The uniform microstructure of the target directly affects the sputtering performance. We have a completed quality management system and we select high purity raw materials and thoroughly blend them to ensure homogeneity. Aluminum Titanium alloy sputtering target is produced by means of vacuum hot pressing method.

Our Aluminum Titanium sputtering targets could provide an outstanding oxidation-resistant nitride coating, Titanium aluminum nitride (TiAlN). TiAlN is the current mainstream as a film for cutting tools, sliding parts and tribo-coatings. It has high hardness, toughness, wear resistant performance and oxidation temperature.

We could produce various kinds of Titanium Aluminum Sputtering Targets