OEM/ODM Factory Iron Sputtering Target of High Quality, Fe Target for Coating

Nickel Iron

While using the “Client-Oriented” organization philosophy, a rigorous top quality command process, highly developed production devices and a potent R&D workforce, we normally provide high quality products, outstanding solutions and aggressive charges for OEM/ODM Factory Iron Sputtering Target of High Quality, Fe Target for Coating, To acquire a consistent, profitable, and constant advancement by getting a competitive advantage, and by continuously increasing the benefit added to our shareholders and our employee.

While using the “Client-Oriented” organization philosophy, a rigorous top quality command process, highly developed production devices and a potent R&D workforce, we normally provide high quality products, outstanding solutions and aggressive charges for China Evaporation Materials and Coating Material, We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable products quality , increase customers’ satisfaction and achieve win-win situation .

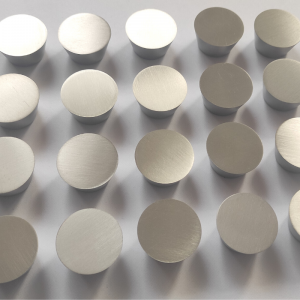

Nickel Iron Sputtering Target Description

Nickel Iron Sputtering Target is manufactured by means of Vacuum Melting, Casting and PM. It has a very high magnetic permeability at low field strength.

A nickel Iron target (Nickel>30 wt%) demonstrates the face-centered cubic structure at room temperature. Conventionally Nickel Iron targets have more than 36% composition of Nickel, and could be divided into four categories: 35%~40% Ni-Fe、45%~50% Ni-Fe、50%~65% Ni-Fe and 70%~81% Ni-Fe. Each could be made into materials with circular, rectangular or plane magnetic hysteresis loops.

Nickel Iron (Ni-Fe) Sputtering Targets are utilized in a wide range of applications, for example magnetic storage media and EMI shielding devices.

Nickel Iron Sputtering Target Packaging

Our Nickel Iron sputter target is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Get Contact

RSM’s Nickel Iron sputtering targets are of ultra high purity and uniform. They are available in various forms, purities, sizes, and prices. We could supply purity 99.99% and our typical compositions: Ni-Fe10at%、N-iFe16at%, Ni-Fe19at%, Ni-Fe20at%, Ni-Fe36at%, Ni-Fe50at%, Ni-Fe70at%.

We specialize in producing high purity thin film coating materials with excellent performance as well as the highest possible density and smallest possible average grain sizes for use in mold coating、decoration、automobile parts、low-E glass、semi-conductor integrated circuit、thin film resistance、graphic display、aerospace、 magnetic recording、touch screen、thin film solar battery and other physical vapor deposition (PVD) applications. Please send us an inquiry for current pricing on sputtering targets and other deposition materials not listed.While using the “Client-Oriented” organization philosophy, a rigorous top quality command process, highly developed production devices and a potent R&D workforce, we normally provide high quality products, outstanding solutions and aggressive charges for OEM/ODM Factory Iron Sputtering Target of High Quality, Fe Target for Coating, To acquire a consistent, profitable, and constant advancement by getting a competitive advantage, and by continuously increasing the benefit added to our shareholders and our employee.

OEM/ODM Factory China Evaporation Materials and Coating Material, We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable products quality , increase customers’ satisfaction and achieve win-win situation .