OEM/ODM Factory Boron Sputtering Target - HEA High-entropy alloy Ti10V20Zr30Nb8Mo30W2 at% Step alloy Titanium Vanadium Zirconium Niobium Molybdenum Tungsten alloy – Rich

OEM/ODM Factory Boron Sputtering Target - HEA High-entropy alloy Ti10V20Zr30Nb8Mo30W2 at% Step alloy Titanium Vanadium Zirconium Niobium Molybdenum Tungsten alloy – Rich Detail:

HEA High-entropy alloy Ti10V20Zr30Nb8Mo30W2 at% Step alloy Titanium Vanadium Zirconium Niobium Molybdenum Tungsten alloy,

high purity factory price primary source,

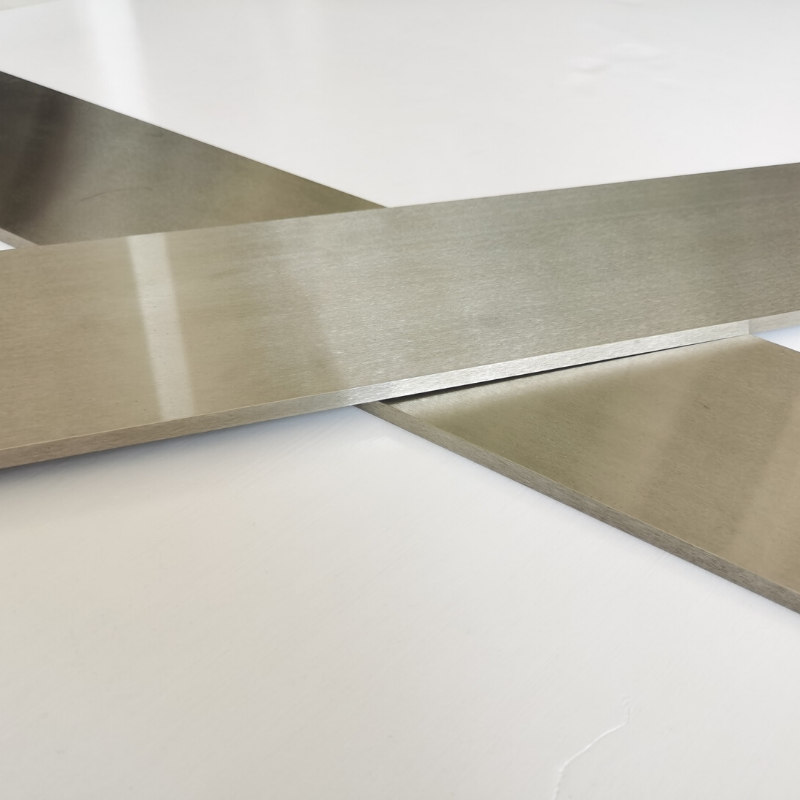

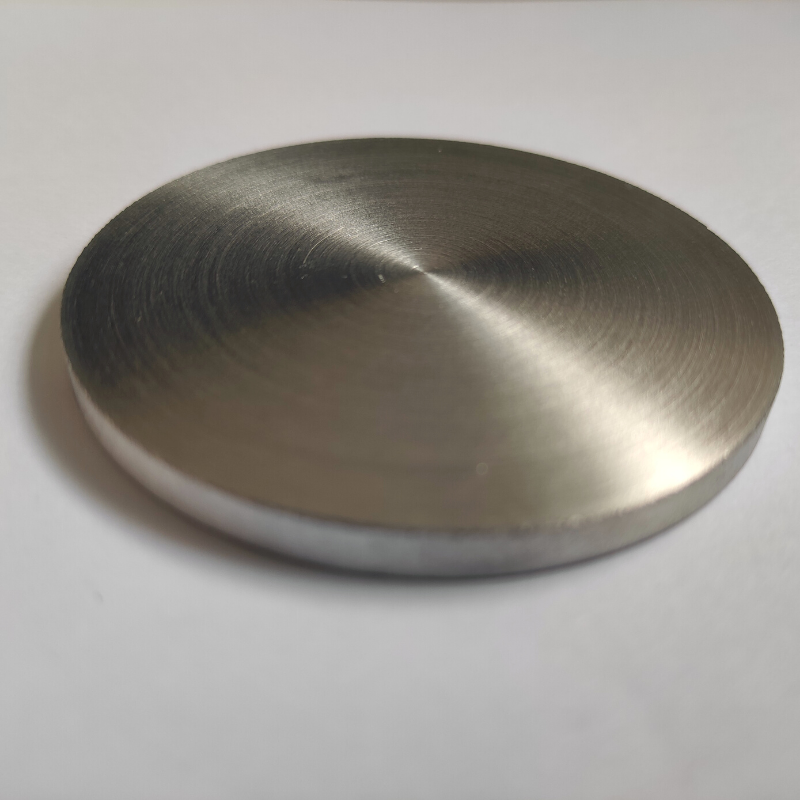

Chromium cobalt sputtering target from Rich Special Materials is a silvery alloy sputtering material containing Cr and Co.

Chromium is a chemical element that originated from the Greek ‘chroma’, meaning color. It was early used before 1 AD and discovered by Terracotta Army. “Cr” is the canonical chemical symbol of chromium. Its atomic number in the periodic table of elements is 24 with a location at Period 4 and Group 6, belonging to the d-block. The relative atomic mass of chromium is 51.9961(6) Dalton, the number in the brackets indicating the uncertainty.

Cobalt is a chemical element that originated from the German word ‘kobald’, meaning goblin. It was first mentioned in 1732 and observed by G. Brandt. “Co” is the canonical chemical symbol of cobalt. Its atomic number in the periodic table of elements is 27 with a location at Period 4 and Group 9, belonging to the d-block. The relative atomic mass of cobalt is 58.933195(5) Dalton, the number in the brackets indicating the uncertainty.

Chronium Cobalt Sputtering Targets are manufactured by means of Vacuum Melting and PM. CrCo has superior specific strength and has been used in various fields where high wear-resistance was needed including aerospace industry, cutlery, bearings, blades, etc.

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Chronium Cobalt Sputtering Materials according to Customers’ specifications. For more information, please contact us.

A high-entropy alloy (HEA) is a metal alloy whose composition consists of significant proportions of five or more metallic elements. HEAs are a subset of multi-principal metal alloys (MPEAs), which are metal alloys that contain two or more primary elements. Like MPEAs, HEAs are renowned for their superior physical and mechanical properties compared to conventional alloys.

HEAs could noticeably improve the hardness, corrosion resistance and thermal and pressure stability, and are widely used in thermoelectric, soft magnetic and radiation tolerant materials.

Product detail pictures:

Related Product Guide:

We have now probably the most innovative production equipment, experienced and qualified engineers and workers, regarded high quality control systems and also a friendly expert income team pre/after-sales support for OEM/ODM Factory Boron Sputtering Target - HEA High-entropy alloy Ti10V20Zr30Nb8Mo30W2 at% Step alloy Titanium Vanadium Zirconium Niobium Molybdenum Tungsten alloy – Rich , The product will supply to all over the world, such as: Latvia, Iraq, Australia, Now, we professionally supplies customers with our main products And our business is not only the "buy" and "sell", but also focus on more. We target to be your loyal supplier and long-term cooperator in China. Now, We hope to be the friends with you.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.