M'mbuyomu, makasitomala ambiri adafunsa anzawo a RSM Technology Department za titaniyamu alloy. Tsopano, ndikufuna ndikufotokozereni mwachidule mfundo zotsatirazi za zomwe zitsulo za titaniyamu zimapangidwa. Ndikukhulupirira atha kukuthandizani.

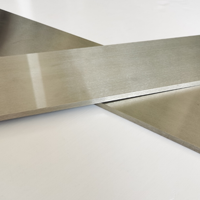

Titaniyamu alloy ndi aloyi opangidwa ndi titaniyamu ndi zinthu zina.

Titaniyamu ndi kristalo wosiyanasiyana, wokhala ndi malo osungunuka a 1720 ℃. Kutentha kukakhala kotsika kuposa 882 ℃, kumakhala kodzaza kwambiri ndi hexagonal lattice, yomwe imatchedwa α Titaniyamu; Ili ndi thupi lokhazikika la cubic pamwamba pa 882 ℃, lomwe limatchedwa β Titanium. Pogwiritsa ntchito mawonekedwe osiyanasiyana a titaniyamu pamwambapa, zinthu zoyenera za aloyi zimawonjezedwa kuti zisinthe pang'onopang'ono kusintha kwa kutentha kwake ndi gawo lokhutira kuti mupeze ma aloyi a titaniyamu okhala ndi mapangidwe osiyanasiyana. Pa kutentha kwa chipinda, titaniyamu aloyi ali ndi mitundu itatu ya matrix, ndipo titaniyamu alloy amagawidwa m'magulu atatu awa: α Alloy (α + β) Alloy ndi β Alloy. Ku China, amawonetsedwa ndi TA, TC ndi TB motsatana.

α titaniyamu aloyi

Ndi α Single gawo aloyi wopangidwa ndi gawo olimba yankho ndi α Gawo, dongosolo lokhazikika, kukana kuvala kwapamwamba kuposa titaniyamu koyera, kukana kwa okosijeni kolimba. Pansi pa kutentha kwa 500 ℃ ~ 600 ℃, imasungabe mphamvu zake ndi kukana kukwawa, koma sangathe kulimbikitsidwa ndi chithandizo cha kutentha, ndipo mphamvu yake ya kutentha siikwera kwambiri.

β titaniyamu aloyi

Ndi β The single-phase alloy yopangidwa ndi gawo solid solution imakhala ndi mphamvu zambiri popanda kutentha. Pambuyo kuzimitsidwa ndi kukalamba, aloyiyo imalimbikitsidwanso, ndipo mphamvu ya kutentha kwa chipinda imatha kufika 1372 ~ 1666 MPa; Komabe, kukhazikika kwa kutentha kumakhala kosauka ndipo sikoyenera kugwiritsidwa ntchito pa kutentha kwakukulu.

α + β titaniyamu aloyi

Ndi aloyi wapawiri gawo lomwe lili ndi zinthu zabwino zonse, kukhazikika kwadongosolo, kulimba kwabwino, pulasitiki komanso kutentha kwambiri. Itha kugwiritsidwa ntchito pakuwotcha kuthamanga, kuzimitsa ndi kukalamba kulimbitsa aloyi. Mphamvu pambuyo mankhwala kutentha ndi za 50% ~ 100% apamwamba kuposa pambuyo annealing; Kutentha kwakukulu kwamphamvu, kumatha kugwira ntchito pa 400 ℃ ~ 500 ℃ kwa nthawi yayitali, ndipo kukhazikika kwake kwamafuta kumakhala kochepa kuposa α Titanium alloy.

Pakati pa ma aloyi atatu a titaniyamu α Titanium alloys ndi α + β Titanium alloy; α Titanium alloy ili ndi makina abwino kwambiri, α + P Titanium alloy imatenga malo achiwiri, β Titanium alloy ndi osauka. α Khodi ya titaniyamu alloy TA, β Khodi ya titaniyamu alloy ndi TB, α+β Khodi ya titaniyamu alloy ndi TC.

Ma aloyi a titaniyamu amatha kugawidwa kukhala ma aloyi osagwira kutentha, ma aloyi amphamvu kwambiri, ma aloyi osagwirizana ndi dzimbiri (titaniyamu molybdenum, titaniyamu palladium aloyi, ndi zina), zotulutsa zotsika kutentha ndi zida zapadera zogwirira ntchito (titaniyamu chitsulo chosungira haidrojeni ndi titaniyamu nickel memory alloys) ) malinga ndi ntchito zawo.

Chithandizo cha kutentha: aloyi ya titaniyamu imatha kupeza mawonekedwe ndi mawonekedwe osiyanasiyana posintha njira yochizira kutentha. Ambiri amakhulupirira kuti fine equiaxed microstructure ali bwino plasticity, matenthedwe bata ndi kutopa mphamvu; Mapangidwe a acicular ali ndi mphamvu zambiri zophulika, mphamvu zokwawa ndi kulimba kwa fracture; Minofu yosakanikirana ya equiax ndi acicular imakhala ndi ntchito zambiri

Nthawi yotumiza: Oct-26-2022