At present, in the world’s major spattering target manufacturers, there are two different methods for the manufacture of aluminum alloy spattering target. One is to choose the casting method to manufacture ingot, and then make the casting process. The other is made by spray molding.Let Beijing editor make up for you to share, about the manufacturing process of titanium aluminum alloy target what are the common sense .

As far as the known casting / casting methods are concerned, when manufacturing the aluminum alloy sputtering target, the aluminum alloy sputtering target is often subject to segregation due to the addition of alloy elements, resulting in poor quality of the sputtered film, and micro particles are easy to occur on the surface of the sputtering target, which will also affect the uniformity of the film properties;However, if the known spray forming method is used to manufacture the aluminum alloy sputtering target, although the above-mentioned related defects can be prevented, the manufacturing cost of the sputtering target will be greatly improved, especially when manufacturing some sputtering targets that are not easy to be cast and must be hot pressed, the cost will be improved by using hot pressing.

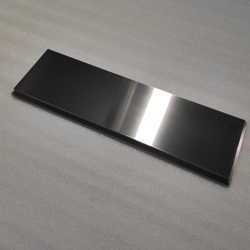

In order to make the manufacturing process of titanium aluminum alloy target easier and lower cost, a method of manufacturing aluminum alloy sputtering target with air spray powder is introduced here. Its principle refers to that a material powder of sputtering target is manufactured by air spray method according to the alloy composition ratio, and then the alloy powder is screened to obtain the appropriate powder particle size. Finally, the powder is vacuum hot pressed to make aluminum alloy sputtering target.

This method of manufacturing aluminum alloy splash targets with air spray powder can be used for manufacturing various aluminum alloy splash targets (aluminum chromium, aluminum silicon copper, aluminum titanium, etc.). The preferred implementation steps are: supplying metal materials for manufacturing aluminum alloy splash targets and melting them into metal melt;Then, the molten metal is made into metal powder by air spray method; Finally, the metal powder is formed by vacuum hot pressing to make aluminum alloy sputtering target, and inert gas is introduced as maintenance gas. This method can prevent data segregation and micro particle defects, and produce high-quality sputtering targets more quickly and cheaply.

Post time: Jun-01-2022