About the application and principle of sputtering target technology, some customers have consulted RSM, now for this problem that more concerned about , technical experts share some specific related knowledge.

Sputtering target application:

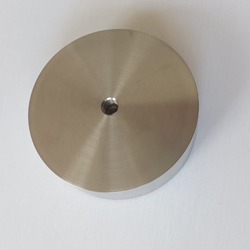

Charging particles (such as argon ions) bombard a solid surface, causing surface particles, such as atoms, molecules or bundles to escape from the surface of the object phenomenon called “sputtering”. In magnetron sputtering coating, the positive ions generated by argon ionization are usually used to bombard the solid (target), and the sputtered neutral atoms are deposited on the substrate (workpiece) to form a film layer. Magnetron sputtering coating has two characteristics: “low temperature” and “fast”.

Magnetron sputtering principle:

An orthogonal magnetic field and electric field are added between the sputtered target pole (cathode) and the anode, and the required inert gas (usually Ar gas) is filled in the high vacuum chamber. The permanent magnet forms a 250-350 Gauss magnetic field on the surface of the target material, and forms an orthogonal electromagnetic field with the high voltage electric field.

Under the action of electric field, Ar gas is ionized into positive ions and electrons, and there is a certain negative high pressure on the target, so the electrons emitted from the target pole are affected by the magnetic field and the ionization probability of the working gas increases. A high-density plasma is formed near the cathode, and Ar ions accelerate to the target surface under the action of Lorentz force and bombard the target surface at a high speed, so that the sputtered atoms on the target escape from the target surface with high kinetic energy and fly to the substrate to form a film according to the principle of momentum conversion.

Magnetron sputtering is generally divided into two kinds: DC sputtering and RF sputtering. The principle of DC sputtering equipment is simple, and the rate is fast when sputtering metal. The use of RF sputtering is more extensive, in addition to sputtering conductive materials, but also sputtering non-conductive materials, but also reactive sputtering preparation of oxides, nitrides and carbides and other compound materials. If the frequency of RF increases, it becomes microwave plasma sputtering. At present, electron cyclotron resonance (ECR) type microwave plasma sputtering is commonly used.

Post time: Aug-01-2022