Nickel-titanium alloy target is a sputtering coating material composed of nickel and titanium, which has shape memory effect and superelastic properties. The name of nickel-titanium alloy is “Nitinol”, also known as shape memory alloy. It has excellent mechanical properties, such as high elastic modulus, high strength and good toughness, so that it can withstand large stresses and deformation. Excellent corrosion resistance, able to maintain its stability in harsh environments for a long time.

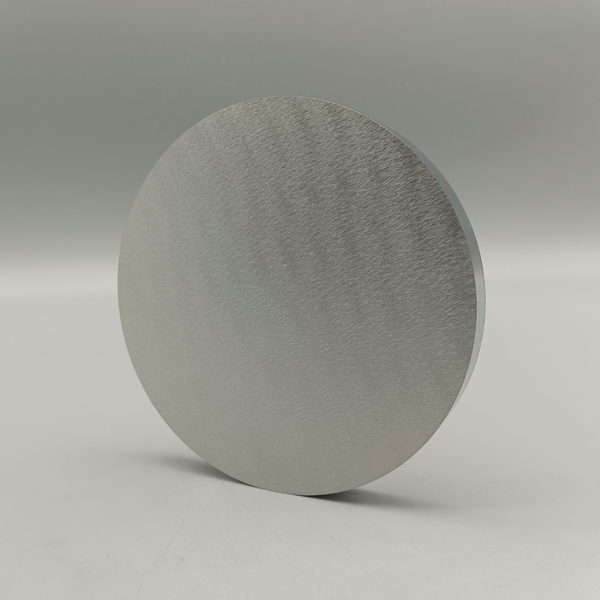

1. NiTi alloy disc material:

In terms of diameter, common are 2 inches (about 50.8 mm), 3 inches (about 76.2 mm), 4 inches (about 101.6 mm) and so on. The thickness is generally about 3-10 mm. Targets of these sizes are widely used in small to medium-sized coating equipment, such as laboratory research equipment and some small industrial coating lines.

2. NiTi alloy rectangular target material:

Common sizes are 100 mm ×100 mm, 150 mm ×150 mm, 200 mm ×200 mm, etc. This rectangular target material is used more in some large coating equipment or scenes requiring large area coating, such as large area glass coating, flat panel display coating and so on.

Outer diameter: The outer diameter of Nitinol tubes for medical implants is usually 0.3-30 mm, and the outer diameter range of some non-medical Nitinol tubes may be larger. Wall thickness: Generally speaking, the wall thickness of nickel-titanium alloy tubes is about 0.1-10 mm. The specific wall thickness will be determined according to factors such as the outer diameter of the pipe, use requirements and application scenarios.

Common Nitinol rods range in diameter from 2 to 200 mm. The length of Nitinol bars is usually about 0.5-3 meters. However, it can also be customized according to the specific needs of customers, and the length range can be adjusted according to the actual application needs.

1. Raw material preparation: Select high-purity nickel and titanium as raw materials to ensure the purity and performance of the target.

2. Melting and casting: nickel and titanium are mixed in a certain proportion and smelted in a protective atmosphere to obtain alloy melt. The melt is then cast into ingots, which are cooled to obtain nickel-titanium ingot.

3. Forging and annealing: the ingot is forged and annealed to eliminate the internal organization and residual stress, and improve the uniformity and stability of the target.

4. Rolling and secondary annealing: rolling and secondary annealing of the forged alloy material to refine the grain and promote the uniformity of the internal structure.

5. Machining and testing: Machining the rolled alloy material, including turning to remove the oxide skin and wire cutting and other steps. Then it is tested, cleaned, dried and packaged, and finally the Nitinol sputtering target is obtained.

2. Biomedical: Used to manufacture various implants, such as cardiovascular stents, orthopedic internal fixation nails, etc. These implants are able to maintain stable shape and performance in the body, facilitating the patient’s recovery. In addition, Nitinol targets are also used to manufacture coatings for medical devices, improving the corrosion resistance and service life of the devices.

3. Mechanical engineering: Used to manufacture high-precision mechanical parts, such as fasteners, springs and transmission devices. These components can maintain stable performance under greater stress and wear, improving the overall operating efficiency of mechanical equipment.

4. Energy engineering: Used to manufacture key components in nuclear power plants and thermal power plants, such as heat exchangers and valves. Its excellent corrosion resistance and thermal stability enable it to operate for long periods in harsh environments.

5. Semiconductor industry: In the semiconductor industry manufacturing, Nitinol can be used to prepare thin films, such as as a buffer layer in power devices.

6. Optical field: used to prepare optical films, such as eye lenses, optical lenses, etc.

7. Other fields: It is also widely used in electronic, chemical and construction fields.

Post time: Dec-02-2024