As a new type of alloy material, nickel-chromium-aluminum-yttrium alloy has been widely used as a coating material on the surface of hot end parts such as aviation and aerospace, gas turbine blades of automobiles and ships, high pressure turbine shells, etc. due to its good heat resistance, corrosion resistance and oxidation resistance.

Our company’s preparation method for Ni-Cr-Al-Y target is vacuum melting method; The general manufacturing process flow is to select nickel blocks and aluminum blocks of different purity according to customer requirements The chrome block and yttrium block are melted under vacuum conditions – select the mold with appropriate size for casting to obtain the ingot required by the customer – carry out the composition test of the ingot – carry out the heat treatment of the ingot according to the characteristics of the target and previous experience – machine the ingot after the heat treatment (including wire cutting, lathe, machining center, etc.) – carry out the special test on the processed target – carry out the target packaging and delivery according to the customer’s requirements.

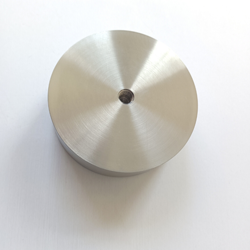

Our advantage is that we can customize the composition and purity according to the customer’s needs. The processed target has high density, no pores, segregation and porosity, uniform structure and beautiful appearance.

Post time: Jan-14-2023