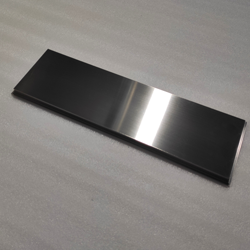

Target is a kind of material often used in the electronic information industry. Although it has a wide range of uses, the ordinary people do not know much about this material. Many people are curious about the production method of target? Next, experts from the Technology Department of RSM will introduce the manufacturing method of the target.

Manufacturing method of target

1. Casting method

The casting method is to melt the alloy raw materials with a certain composition ratio, and then pour the alloy solution obtained after melting into the mold to form the ingot, and then form the target after mechanical processing. The casting method generally needs to be melted and cast in vacuum. The common casting methods include vacuum induction melting, vacuum arc melting and vacuum electron bombardment melting. Its advantages are that the target produced has low impurity content, high density and can be produced in large scale; The disadvantage is that when melting two or more metals with large difference in melting point and density, it is difficult to make alloy target with uniform composition by conventional melting method.

2. Powder metallurgy method

The powder metallurgy method is to melt the alloy raw materials with a certain composition ratio, then cast the alloy solution obtained after melting into ingots, crush the cast ingots, press the crushed powder into shape, and then sinter at high temperature to form targets. The target made in this way has the advantages of uniform composition; The disadvantages are low density and high impurity content. The commonly used powder metallurgy industry includes cold pressing, vacuum hot pressing and hot isostatic pressing.

Post time: Aug-15-2022