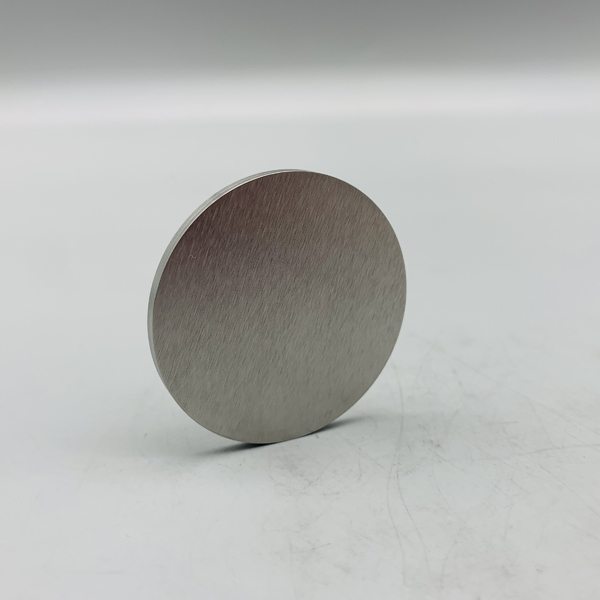

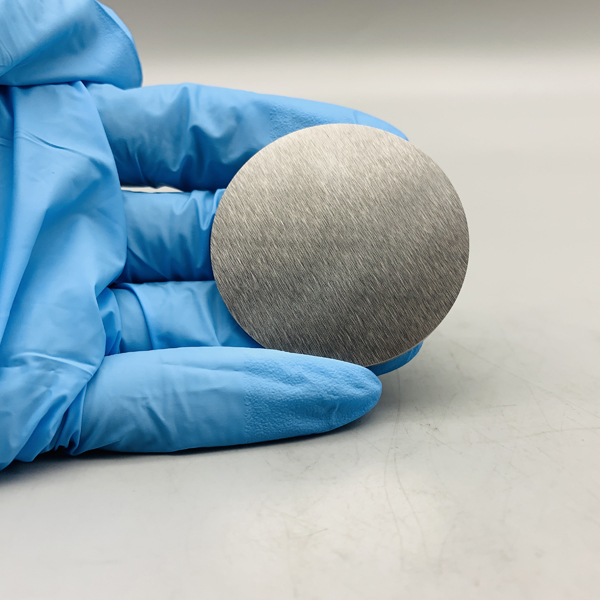

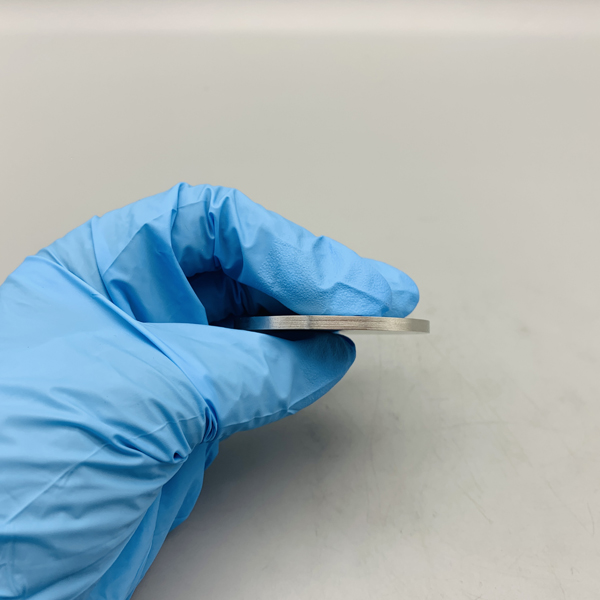

Fe-silicon-boron-carbon alloy target is an alloy material composed of iron (Fe), silicon (Si), boron (B) and carbon (C), which is specially used for the target in the sputtering coating process. Fe-silicon-boron-carbon alloy target material has the characteristics of high purity, good physical and chemical stability, and is widely used in the fields of electronics, mold coating, decorative coating and so on.

FeSiBC target characteristics:

2. Iron silicon boron carbon thin film coating materials with adjustable composition: According to different application requirements, the ratio of iron, silicon, boron and carbon in the alloy target can be adjusted to meet the requirements of the specific coating process.

3. FeSiBC pvd target with good sputtering performance: In the process of sputtering coating, the iron-silicon-boron-carbon alloy target can stably sputter out the required alloy components to form a uniform and dense coating layer.

4. FeSiBC multicomponent alloy target with good stability: the alloy target shows good physical and chemical stability during the coating process, which is not easy to react with the coating environment, so as to ensure the quality and performance of the coating layer.

FeSiBC alloy target production procedure:

Iron-silicon-boron alloy targets are usually made by smelting. Each step requires strict control of process parameters and quality requirements.

Electronics industry: Used in the coating process of electronic components such as thin film transistors (TFT), solar cells, integrated circuits, etc., to improve the performance and stability of electronic components.

Optical field: In the preparation of optical films, iron-siliconboron-carbon alloy targets can be used to form coatings with specific optical properties, such as reflective films, anti-reflection films, etc.

Die coating: used to improve the wear resistance, corrosion resistance and service life of the die, reduce production costs.

Decorative coatings: In the field of decoration, iron-silicon-boron-carbon alloy targets can be used to prepare decorative coatings with a specific color, gloss and texture to enhance the beauty and added value of the product.

Post time: Dec-02-2024