Inconel is a superalloy, Inconel 600 is often referred to as “GH3600″ “GH600″ is a nickel-based superalloy. It has good high temperature performance, corrosion resistance and good mechanical strength. Suitable for use in high temperature, high pressure and corrosion resistant environments. It is widely used in aerospace, petrochemical, nuclear energy and medical fields.

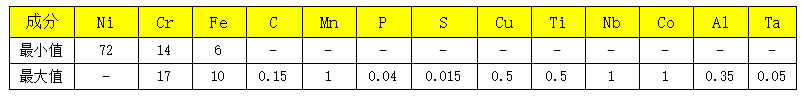

Inconel 600 is mainly composed of nickel (Ni) and chromium (Cr), and its chemical composition also includes a small amount of iron (Fe), carbon (C), silicon (Si), manganese (Mn), sulfur (S) and other elements. The specific chemical composition ratio is as follows:

Inconel600 characteristic:

Physical properties:

Density: 8.43-8.47g /cm³ Melting point: 1370-1425°C3 Thermal conductivity: 14.8W /(m·K)

Linear expansion coefficient: 13.3 × 10⁻⁶/K Tensile strength: 550 MPa Yield strength: 240 MPa

Elongation: 30%

Corrosion resistance: Inconel 600 performs well in various acidic (such as sulfuric acid, phosphoric acid, hydrochloric acid, etc.) and alkaline solutions, as well as in chloride media. The addition of chromium significantly improves the oxidation resistance of the alloy, so that it can run stably in high temperature and corrosive environment for a long time, and is not easy to appear oxidation damage.

High temperature strength: The alloy has excellent high temperature strength and can maintain high mechanical properties even at high temperatures. Its tensile strength can reach 550 MPa at room temperature, and its yield strength is about 240 MPa.

Machinability: Inconel 600 has good machinability and can be formed by forging, rolling, welding and other processes. Its rational chemical composition design makes the alloy easy to process and adapt to complex manufacturing requirements.

Oxidation resistance: Chromium in the alloy can form a dense oxide film, which effectively protects the alloy from oxidative corrosion.

Thermal shock resistance: Cornel 600 alloy can withstand rapid temperature changes without cracking.

Inconel 600 Production technology:

Post time: Dec-02-2024