With the improvement of people’s living standards and the continuous development of science and technology, people have higher and higher requirements for the performance of wear-resistant, corrosion-resistant and high-temperature resistant decoration coating products. Of course, the coating can also beautify the color of these objects. Then, what is the difference between the treatment of electroplating target and sputtering target? Let experts from the Technology Department of RSM explain it for you.

Electroplating target

The principle of electroplating is consistent with that of electrolytic refining copper. When electroplating, the electrolyte containing the metal ions of the plating layer is generally used to prepare the plating solution; Immersing the metal product to be plated into the plating solution and connecting it with the negative electrode of the DC power supply as the cathode; The coated metal is used as the anode and connected to the positive electrode of the DC power supply. When the low-voltage DC current is applied, the anode metal dissolves in the solution and becomes a cation and moves to the cathode. These ions obtain electrons at the cathode and are reduced to metal, which is covered on the metal products to be plated.

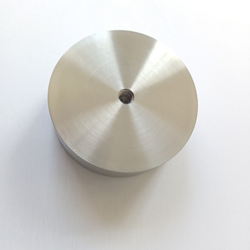

Sputtering Target

The principle is mainly to use glow discharge to bombard argon ions on the target surface, and the atoms of the target are ejected and deposited on the substrate surface to form a thin film. The properties and uniformity of sputtered films are better than those of vapor deposited films, but the deposition speed is much slower than that of vapor deposited films. New sputtering equipment almost uses strong magnets to spiral electrons to accelerate the ionization of argon around the target, which increases the probability of collision between the target and argon ions and improves the sputtering rate. Most of the metal plating films are DC sputtering, while the non-conductive ceramic magnetic materials are RF AC sputtering. The basic principle is to use glow discharge in vacuum to bombard the surface of the target with argon ions. The cations in the plasma will accelerate to rush to the negative electrode surface as the sputtered material. This bombardment will make the target material fly out and deposit on the substrate to form a thin film.

Selection criteria of target materials

(1) The target should have good mechanical strength and chemical stability after film formation;

(2) The film material for the reactive sputtering film must be easy to form a compound film with the reaction gas;

(3) The target and the substrate must be firmly assembled, otherwise, the film material with good binding force with the substrate shall be adopted, and a bottom film shall be sputtered first, and then the required film layer shall be prepared;

(4) On the premise of meeting the film performance requirements, the smaller the difference between the thermal expansion coefficient of the target and the substrate, the better, so as to reduce the influence of the thermal stress of the sputtered film;

(5) According to the application and performance requirements of the film, the target used must meet the technical requirements of purity, impurity content, component uniformity, machining accuracy, etc.

Post time: Aug-12-2022