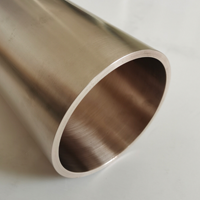

With the increasing market demand for targets, there are more and more kinds of targets, such as alloy targets, sputtering targets, ceramic targets, etc. What are the technical knowledge about copper targets? Now let’s share the technical knowledge of copper targets with us ,

1. Determination of dimension and tolerance range

According to actual needs, copper targets need high-precision appearance dimensions, and targets with certain specifications and deviations are provided according to customer requirements.

2. Purity requirements

The purity requirements are mainly determined according to the use of customers and based on satisfaction with customers’ needs.

3. Microstructure requirements

① Grain size: the grain size of the target affects the sputtering performance of the target. Therefore, the grain size is mainly based on the customer’s use requirements, through a series of forging heat treatment to meet the user’s requirements.

② Crystal direction: according to the structural characteristics of the copper target, different forming methods are adopted, and the heat treatment process is controlled according to the user’s requirements.

4. Appearance quality requirements

The surface of the target must be free of factors that cause poor use, and the quality of the sputtering process must be guaranteed according to the customer’s requirements.

5. Requirements for welding bond ratio

If the copper target is welded with other materials before sputtering, ultrasonic inspection must be carried out after welding to ensure that the non bonding area of the two is ≥ 95%, meeting the requirements of high-power sputtering without falling off. Ultrasonic testing is not required for all-in-one type.

6. Internal quality requirements

In view of the service conditions of the target, the target needs to be free of defects such as pores and inclusions. It is determined through negotiation with the customer according to the actual needs.

After the target is thoroughly cleaned to ensure that the surface of the target is free of dirt and particle attachments, it is directly vacuum packed according to the requirements of customers.

Post time: Jul-05-2022