What is cobalt chromium molybdenum alloy ?

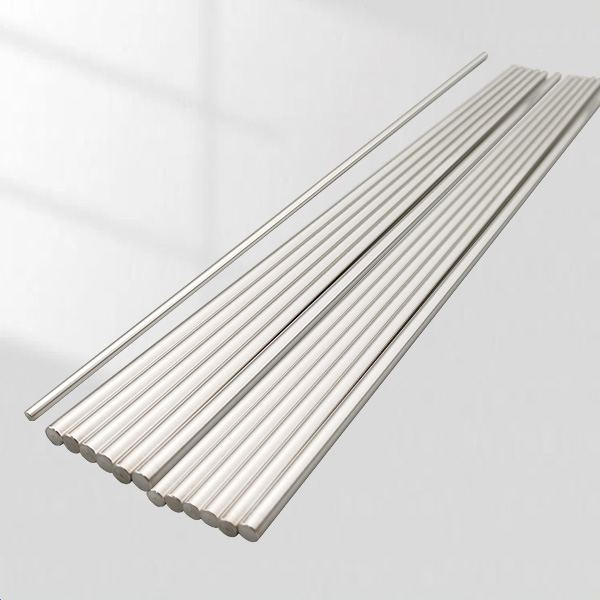

Cobalt Chromium Molybdenum alloy (CoCrMo) is a kind of wear and corrosion resistance of cobalt-based alloy, is also commonly known as Stellite (Stellite) alloy.

What is the material characteristics of cobalt chromium molybdenum alloy ?

1.structural features

Cobalt-chrome-molybdenum alloy is composed of cobalt, chromium, molybdenum and other elements, and through melting, forging and other processes. It has small grain size and dense structure, so it has high toughness and tensile strength, but also has high thermal stability and corrosion resistance.

2.physical characteristics

The density of cobalt-chromium-molybdenum alloy is relatively large, about 8.5g/cm³, and the melting point is also high, which can reach more than 1500℃. In addition, cobalt-chrome-molybdenum alloys have low thermal conductivity and thermal expansion coefficient, making them very suitable for high temperature.

3.Mechanical property

Cobalt-chromium-molybdenum alloy has very high material hardness and wear resistance, and it also has high plasticity and strength. This characteristic allows it to withstand very high pressures and heavy loads without plastic deformation or damage

4.Corrosion resistance

Cobalt-chrome-molybdenum alloy has good corrosion resistance in acid, alkali, hydrogen, salt water and fresh water and other environments. Due to its high stability and corrosion resistance, this alloy has a wide range of applications in many fields.

Cobalt-chrome-molybdenum alloy is commonly used in the manufacture of parts and components under special working environments such as high strength, high temperature and high pressure.

Post time: Jun-29-2024