Sputtering target is a material widely used in physical vapor deposition (PVD) technology.

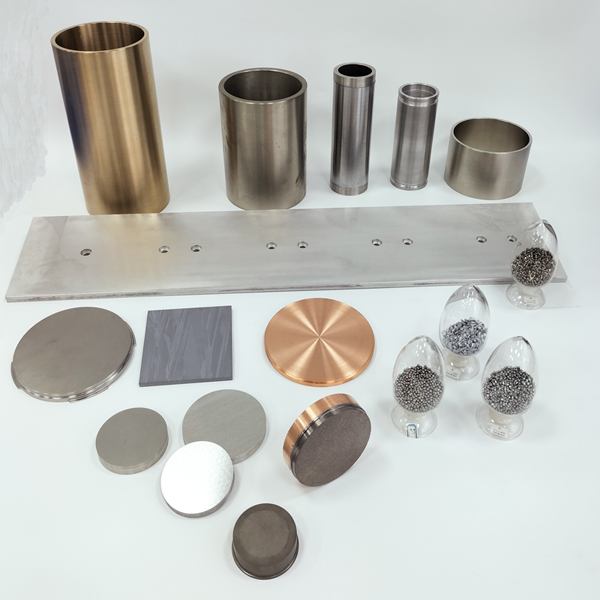

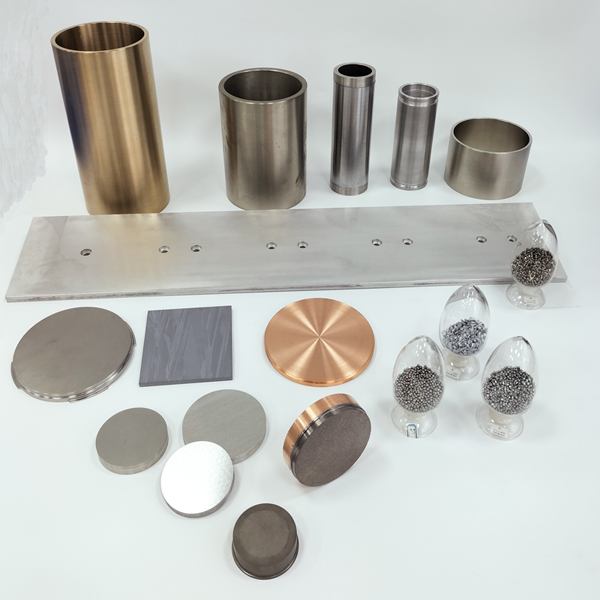

Sputtering target classification by Shape:

Square target: The shape is square, in some specific sputtering equipment or process, the use of square target can better adapt to the shape and size of the substrate, so as to achieve more uniform film deposition, improve the quality and performance of the film, often in the field of flat display.

Round target: the most common shape, with good symmetry and uniformity, in the sputtering process, the Angle and distance of ion bombardment on the surface of the round target are relatively consistent, to ensure that the sputtered atoms or particles are uniformly deposited on the substrate, widely used in various sputtering coating processes.

Special-shaped target: refers to the irregular shape, non-traditional square or round target of the special shape of the target, mainly to meet some special application needs or to adapt to the specific shape of the base and design and manufacture, such as some with complex curved surfaces or special structure of the base coating.

Classification by chemical composition

Metal target: composed of a single metal element, such as aluminum target, titanium target, copper target, tantalum target, nickel target, zinc target, chromium target, magnesium target, niobium target, tin target, iron target, zirconium target, germanium target, silver target, cobalt target, gold target, gadolinium target, lanthanum target, yttrium target, cerium target, tungsten target, has good electrical conductivity, thermal conductivity and ductility, etc., in the electronic, electrical, mechanical and other fields have a wide range of applications.

Alloy target: It is composed of two or more kinds of metal elements, such as nickel-chromium alloy target, nickel-vanadium alloy target, aluminum-silicon alloy target, nickel-copper alloy target, titanium-aluminum alloy target, boron-iron alloy target, ferrosilicon alloy target, etc., through reasonable adjustment of alloy composition, you can obtain better performance than a single metal, such as higher hardness, strength, corrosion resistance, etc., often used for film preparation requiring special properties.

Ceramic compound target material: Including oxides, nitrides, carbides, sulfides, silicates and other ceramic materials made of targets, Such as ITO target (indium tin oxide), AZO Target (zinc and aluminum oxide), magnesium oxide target, iron oxide target, silicon nitride target, silicon carbide target, titanium nitride target, chromium oxide target, zinc oxide target, zinc sulfide target, silicon oxide target, cerium oxide target, zirconium dioxide target, niobium pentoxide target, tungsten trioxide target, aluminum oxide target, tantalum pentoxide target, boron nitride target, lithium niobate target, praseodymium titanate target, Barium titanate target, lanthanum titanate target Ceramic compound targets have unique physical and chemical properties, such as high hardness, high melting point, good insulation, optical properties, etc., and have important applications in electronics, optics, energy and other fields.

Classification by Application Field

Semiconductor – related Target: Mainly used for film deposition in the manufacturing process of semiconductor integrated circuits. For example, “target materials for electrode wiring films”, “target materials for barrier films”, etc. They have extremely high requirements for the purity, impurity content and microstructure of target materials, usually requiring a purity of 99.999% or even higher.

Recording Medium Target: It can be divided into two categories: target materials for magnetic recording media and target materials for optical recording media. The target materials for magnetic recording media mainly include cobalt – chromium – based alloys and iron and iron oxide target materials, etc., which are used to prepare films of magnetic recording media such as hard disks and magnetic tapes; the common film layers of optical recording media include reflective films, recording films, protective films, etc. For example, the reflective film is made by sputtering and depositing a pure aluminum or aluminum alloy target material, and the recording film is made by sputtering and depositing a rare – earth – transition – metal target material.

Display Target: Used for film preparation of flat – panel display devices such as liquid – crystal displays (LCD) and organic light – emitting diode displays (OLED). The common one is ITO target material, which is used to prepare transparent conductive films. In addition, there are target materials for preparing electrode wiring films, light – shielding films, electroluminescent film – emitting layers, insulating layers, etc.

Superconducting Ceramic Target: Used to prepare superconducting films. Superconducting materials have the characteristics of zero resistance and complete diamagnetism, etc., and have huge application potential in energy, communication, transportation and other fields. The research and development and application of superconducting ceramic target materials are of great significance for promoting the development of superconducting technology.

Giant MagnetoresistanceTarget: The giant magnetoresistance effect refers to the phenomenon that the resistance of a material changes significantly under a certain magnetic field. Giant magnetoresistance ceramic target materials can be used to prepare film materials with the giant magnetoresistance effect and have important applications in magnetic sensors and magnetic storage fields.

Post time:

Dec-03-2024