Cracks in sputtering targets usually occur in ceramic sputtering targets such as oxides, carbides, nitrides, and brittle materials such as chromium, antimony, bismuth. Now let the technical experts of RSM explain why the sputtering target crack and what preventive measures can be taken to avoid this situation.

Ceramic or brittle material targets always contain inherent stresses. These internal stresses are generated in the target manufacturing process. In addition, these stresses are not completely eliminated by the annealing process, because they are inherent characteristics of these materials. In the sputtering process, the bombardment of gas ions transfers their momentum to the target atoms, providing them with enough energy to separate them from the lattice. This exothermic momentum transfer makes the target temperature rise, which may reach 1000000 ℃ at the atomic level.

These thermal shocks increase the existing internal stress in the target to many times. In this case, if the heat is not properly dissipated, the target may break. In order to prevent the target from cracking, heat dissipation should be emphasized. A water cooling mechanism is required to remove unwanted heat energy from the target. Another issue to consider is the increase in power. Too much power applied in a short time will also cause thermal shock to the target. In addition, we suggest binding these targets to the backplane, which can not only provide support for the target, but also promote better heat exchange between the target and water. If the target has cracks but is bonded with the back plate, it can still be used.

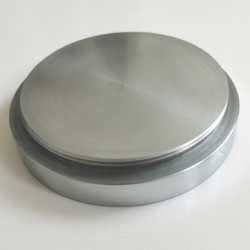

Rich Special Materials Co., Ltd. can provide sputtering targets with backplane. It can be customized according to the customers’s requirements of material, thickness and bonding type .

Post time: Sep-21-2022