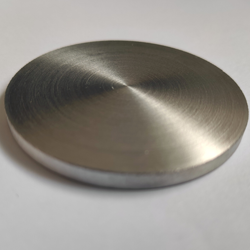

Before a customer consulted about the reason why the color of the vacuum coating target material turns black, presumably there will be other customers have encountered this or similar problems, now let the experts of RSM technology Department explain to us about the reasons why the vacuum coating target material turns black?

For: the color of the upper and lower plates of vacuum coating does not match, and the color of both ends of one plate is different (we produce rose gold). In addition, what is the reason for the black color? The analysis is as follows:

The black color is caused by the low residual air and vacuum in the furnace body. Your color inconsistency may be due to the difference between the position of your target and the position of the substrate.

The application of vacuum technology has the following points:

1. Application in the field of optical film: anti-reflection film, high reflective film, cut-off filter, anti-counterfeiting film, etc.

2. Application in building glass: sunlight control film, low radiation glass, anti-fog and anti-dew and self-cleaning glass, etc.

3, in the application of protective coating: aircraft engine blade, automobile steel plate, heat sink, etc.

4, in the application of hard coating: cutting tools, molds and wear resistant corrosion parts, etc.

5. Application in the field of solar energy utilization: solar collector tube, solar cell, etc.

6, application in integrated circuit manufacturing: film resistor, film capacitor, film temperature sensor, etc.

7. Applications in the field of information storage: magnetic information storage, magneto-optical information storage, etc.

8, in the field of information display applications: liquid crystal screen, plasma screen, etc.

9, in the application of decorative ornaments: mobile phone case, watch case, glasses frame, hardware, small ornaments and other coating.

Post time: Aug-02-2022