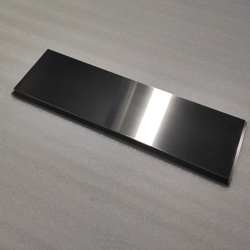

AZO sputtering targets are also referred to as aluminum-doped zinc oxide sputtering targets. Aluminum-doped zinc oxide is a transparent conducting oxide. This oxide is insoluble in water but is thermally stable. AZO sputtering targets are typically used for thin-film deposition.So what kind of fields are they mainly used in? Now let’s the editor from RSM share with you

Main application fields:

Thin-film Photovoltaics

Thin-film photovoltaics use semiconductors to convert light into electricity. In this case, the AZO sputtering target provides the AZO target atoms used to make the thin films on the photovoltaic. The AZO thin film layer permits photons to enter the solar cells. The photons generate electrons which the AZO thin film transports.

Liquid-Crystal Displays (LCDs)

AZO sputtering targets are sometimes employed in making LCDs. Although OLEDs are gradually replacing LCDs, LCDs are used in making computer monitors, television screens, phone screens, digital cameras, and instrument panels. They generally do not consume much power and as such do not emit much heat. In addition, because AZO is non-toxic, LCDs do not emit toxic radiation.

Light Emitting Diodes (LEDs)

An LED is a semiconductor that produces light when current flows through it. Since aluminum-doped zinc oxide is a semiconductor with high electrical conductance and optical transmittance, it is usually used in making LEDs. LEDs can be used for illumination, signs, data transmission, machine vision systems, and even biological detection.

Architectural Coatings

AZO sputtering targets are used in various architectural coatings. They provide the target atoms for the architectural coatings.

Post time: Nov-23-2022