Alloys based on silver and other metals. There are many types of silver alloys, the most important of which are: silver-copper alloys, silver-magnesium alloys, silver-nickel alloys, silver-tungsten alloys, silver-iron alloys and silver-cerium alloys.

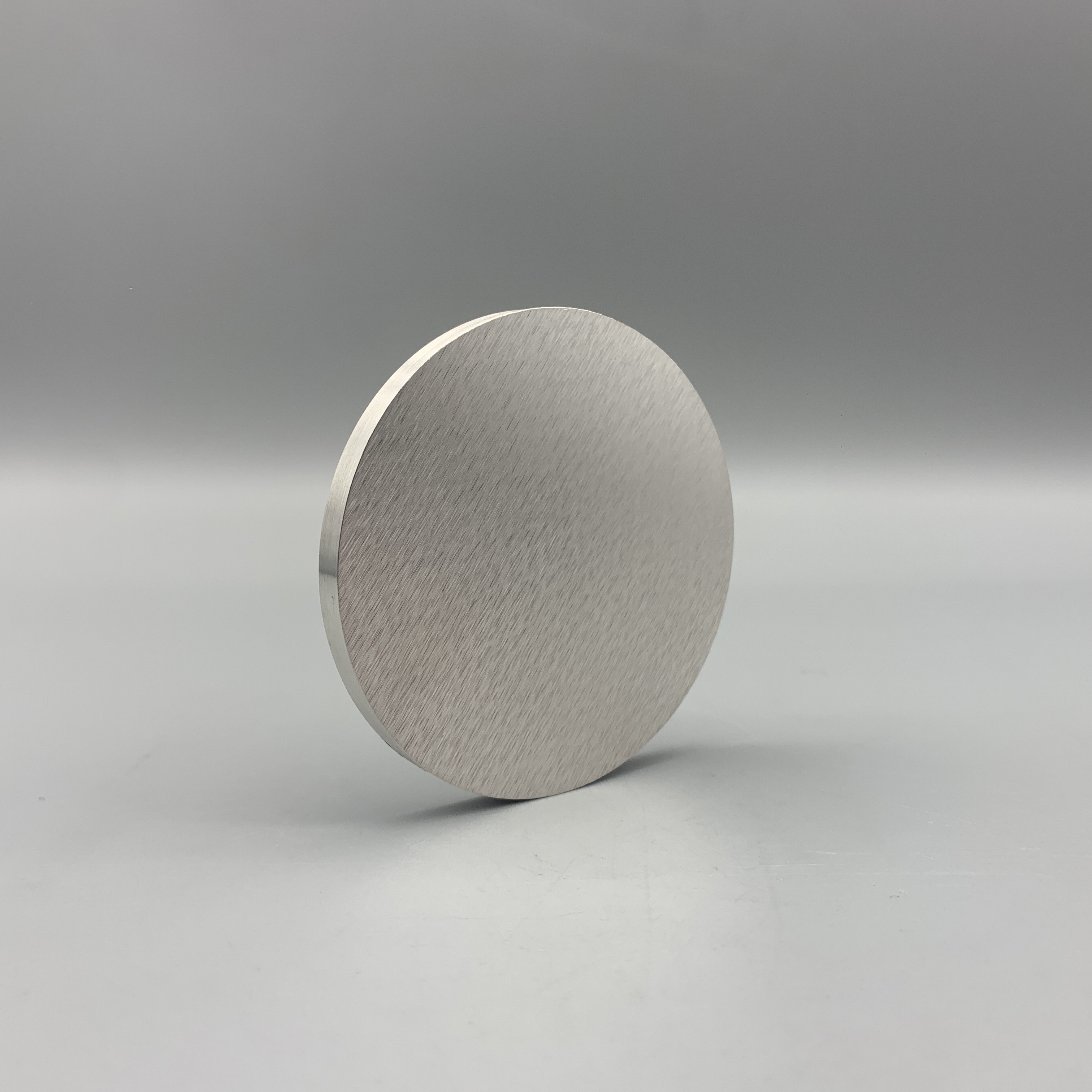

Precious metal materials with silver as the main component. Generally use pure silver or high purity silver (99.9*** above) as raw materials, should avoid bismuth, lead, antimony and other harmful impurities. Silver can be formed with many elements in solid solution, intermetallic compounds or intermediate phase, as well as many kinds of composite materials (false alloy). Depending on the needs, they can be made into binary, ternary or polyalloys. Silver alloys are widely used in many areas of industrial technology.

The main applications of silver alloys are:

(1) silver-based brazing material, mainly silver-copper-zinc alloys as the basis for the composition of the alloy series, such as AgCuZn system, AgCuZnCd system, AgCuZnNi system; silver-nickel alloy, silver-copper alloy;

Containing 90% silver and 10% copper alloy called currency silver, melting point 875 ℃; containing 80% silver and 20% copper alloy called fine work silver, melting point 814 ℃; containing 40% or 60% silver and copper, zinc, cadmium alloys called silver solder, melting point greater than 600 ℃. Mainly used to connect the higher strength requirements of metal products.

(2) silver-based contact materials, mainly silver-copper alloy (AgCu3, AgCu7.5), and silver-cadmium oxide alloy and silver-nickel alloy;

(3) silver-based resistance materials, silver manganese tin alloy resistance coefficient is moderate, resistance temperature coefficient is low, the copper thermal potential is small, can be used as a standard resistor and potentiometer winding materials; silver molybdenum alloy, silver tungsten alloy, silver ferroalloy, silver cadmium alloy;

(4) silver-based plating materials, commonly used silver-tin alloy AgSn3 ~ 5, AgPb0.4 ~ 0.7, AgPd3 ~ 5 and so on;

(5) silver-based dental materials, silver amalgam, also known as amalgam, is mercury as a solvent, silver-copper-tin-zinc as an alloy powder, the reaction occurs through the grinding and the formation of a kind of alloy, is the more ideal veneer materials. Silver amalgam AgxHg, white uneven brittle solid. Its composition varies depending on the formation temperature; Ag13Hg (445°C), Ag11Hg (357°C), Ag4Hg (302°C), AgHg2 (less than 300°C)

Silver alloy properties improve.

Silver is extremely soft and easy to work. In order to improve its strength and hardness and increase its wear resistance, long ago people added copper to silver to make silver-copper alloys, which are used in jewelry, tableware and silver coins. In order to improve the performance of silver-copper alloy, often add nickel, beryllium, vanadium, lithium and other third group of elements into ternary alloys. In addition, there are many other elements added to silver can also play a role in strengthening.

Although silver is inert in the organic atmosphere, but it is easy to be sulfur-containing atmosphere corrosion and sulfide. Improvement of silver sulfide resistance is also through the means of alloying, such as the addition of gold and palladium can reduce the rate of silver sulfide film generation. In addition, many base metal elements such as manganese, antimony, tin, germanium, arsenic, gallium, indium, aluminum, zinc, nickel, vanadium into the silver can also improve its anti-sulfuration properties. Silver-based electrical contact materials are many types, there are alloy state, there are also used in powder metallurgy methods made of false alloy, the purpose is to strengthen, wear-resistant and improve the electrical contact properties.

Translated with DeepL.com (free version)

Post time: Mar-07-2024