In many fields of modern science and technology, sputtering targets play an indispensable role. Its unique physical properties and preparation process enable it to be widely used in several key industries.

In the field of display coating, sputtering targets are mainly used to prepare thin film materials for various display devices, such as liquid crystal display (LCD), TN, STN, TFT-LCD, FED, PDP, OLED and CF (color filter) and other display basic components. Organic light-emitting diode (OLED) and so on. High purity aluminum target, high purity copper target, ITO target, molybdenum and molybdenum alloy target. Molybdenum and molybdenum alloy sputtering targets have been widely used in electronic components and electronic products, such as thin film semiconductor tube – liquid crystal display (TFT-LCD), plasma display, field emission display, touch screen and so on. Molybdenum-niobium alloy targets are also used in flat display and touch screen, TFT-LCD screen and photovoltaic field.

Our company can provide customers with display coating commonly used targets are: Mo target, MoNa target, high purity Cu target, high purity Al target, ITO target, AlNd target and so on. The choice of target depends on the specific application requirements and process requirements.

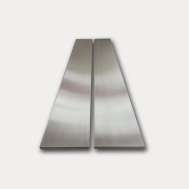

High purtiy Al target Cu target Mo target MoNb Alloy target

Sputtering targets are widely used in the field of glass coating. Specifically, the sputtering target is mainly used to make low-radiation coated glass (Low-E glass), which is also known as energy-saving glass. It is widely used in building external walls, Windows, doors and other parts in the construction field: in the field of home appliances, it can be used as a thermal insulation material to improve the energy efficiency and thermal insulation performance of products. The automotive sector is used as automotive windshield and side window glass. With the demand for energy saving, emission reduction and improving the quality of life, traditional architectural glass is gradually being replaced by this energy-saving glass.

Our company can provide customers with glass coating commonly used targets are: NiCr target, Cr target, Ti target, Al target, Ag target, AZO target, ITO target and so on.

Al target NiCr alloy target Cr sputtering target Ti sputtering target

Sputtering target plays an important role in the application of EMI coating. The conductive film prepared by sputtering coating technology has excellent conductive properties and electromagnetic shielding effect, which provides effective electromagnetic interference protection for electronic equipment.

Our company can provide customers with EMI coating commonly used targets: aluminum targets, copper targets, silver targets, nickel chromium targets, ITO targets, and other oxide targets (such as zinc oxide, titanium oxide, etc.).

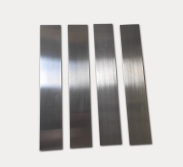

Nicr target Al target Cu target Ag target

Decorative coating (Decorative coating) is a specific process to form a decorative film on the surface of the object.

The purpose of decorative coating is mainly to improve the appearance of the workpiece decorative performance and color at the same time to make the workpiece more wear and corrosion resistant to extend its service life, the main application areas are traditional watches, hardware jewelry, smart wear accessories, through PVD technology can be in these application areas accessories surface to produce a variety of metal film, such as gold, silver, black, gray, color and so on. With the continuous improvement of people’s living standards, more and more daily necessities need decorative coating, so the demand for decorative coating targets is increasing.

Our company can provide customers with decorative coating commonly used targets are: Cr target, Ti target, Zr target, Ni target, W target, TiAl target, imitation gold copper target. The choice of target depends on the specific application requirements and process requirements.

Zr sputtering target TiAl alloy target Ti target Cr target

Sputtering target is the key material for hard coating preparation, and its quality directly affects the performance of coating. Hard coating requires higher performance. At present, common hard coatings include Cr, TiAl, AlCr and so on. The choice of target depends on the specific application requirements and process requirements.

Our company can provide customers with hard coating commonly used targets: Cr target, TiAl target, TiSi target, AlCr target, CrAlSi target, WC target and so on.

Cr target TiAl alloy target AlCr alloy target TiSi alloy target

Sputtering targets play a crucial role in semiconductor chip manufacturing. It is mainly used to form various thin film layers inside the chip, such as conductive layer, insulating layer, semiconductor layer, barrier layer, etc.

high purity metal sputtering targets, such as copper, aluminum, etc., are widely used to form conductive lines and contact points inside chips. Through the sputtering process, these metal targets can be deposited on the silicon wafer under precise conditions to build a complex and fine circuit pattern, and ceramic targets such as oxides and nitrides can be used to form an insulation layer or a barrier layer.

Sputtering target is the key raw material for the preparation of integrated circuits. The technical requirements are the highest, requiring ultra-high purity metals, high-precision dimensions and high integration. The quality and performance of the sputtering target have an important influence on the performance and reliability of semiconductor chips. Therefore, when selecting the sputtering target, it is necessary to consider its purity, density, crystallinity, surface roughness and other factors, and select according to the specific process requirements and application scenarios.

In solar panels, sputtering targets are mainly used to form key films such as conductive layers, barrier layers and transparent conductive layers. For example, aluminum targets and copper targets may be used to form conductive layers that provide transport channels for electrical current. Molybdenum and chromium targets may be used to form a barrier layer to prevent leakage of current. In addition, transparent conductive targets such as ITO targets and AZO targets are also very important in solar panels, allowing sunlight to penetrate while providing the necessary electrical conductivity.

Post time: Dec-03-2024