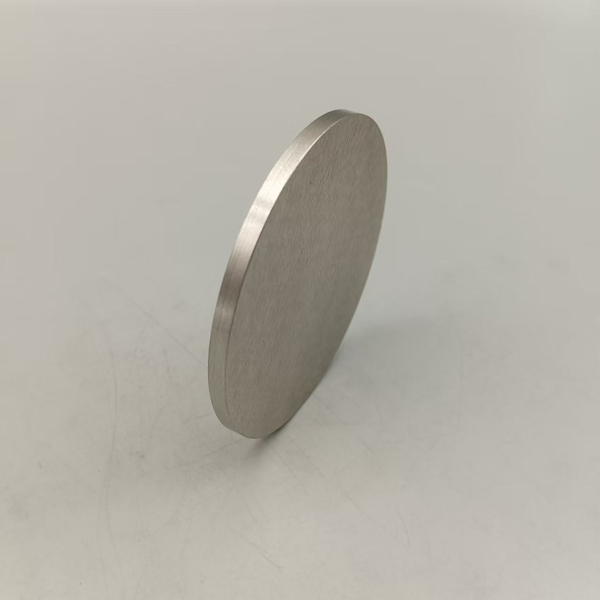

1J85 Iron nickel molybdenum soft magnetic alloy is an iron nickel base alloy, mainly composed of iron, nickel and molybdenum and other elements, is a high performance magnetic material. It has excellent soft magnetic properties such as high initial permeability and low coercivity. Widely used in the electronics industry, often used in transformer core, magnetic head, magnetic shielding, etc., can reduce loss, improve the efficiency of electromagnetic conversion and signal induction.

1J85 nickel alloy soft magnetic alloy features include:

Low coercivity: 1J85 alloys have A very low coercivity, usually between 1.5 A/m and 2.5 A/m. The low coercivity means that the alloy is easy to magnetize and demagnetize, which is conducive to reducing hysteresis loss and improving the efficiency of electromagnetic equipment.

Good temperature stability: The magnetic properties of 1J85 alloy remain stable over a wide temperature range, and can adapt to the needs of a variety of working environments.

In the entire 1J85 alloy production process, the process parameters of each link need to be strictly controlled to ensure the quality and performance of the final product.

1. Vacuum induction melting: This is one of the most commonly used preparation methods. The alloy raw material is melted by induction heating under vacuum conditions, and refined and degassed during the smelting process to obtain high quality alloy ingot.

Post time: Dec-03-2024