Newly Arrival Electron-Beam Melting - Pbbi Alloy Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich

Newly Arrival Electron-Beam Melting - Pbbi Alloy Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich Detail:

Lead-Bismuth Sputtering Target Description

Lead Bismuth alloy is known for its low melting point. Low melting temperature alloys usually contain about 20% to 25% lead, Bismuth, and sometimes other metals, like Tin, Cadmium, or Indium. They are widely used in optical industry for lens blocking, work-holding in precision engineering, prototyping, safety valves, press tools for limited runs, tube bending for complicated profiles, radiotherapy to construct shielding blocks and many other applications.

Lead-Bismuth alloy has a melting point of 124°C, it is a suitable material for coolant in nuclear reactors, Hydrogen production, and spallation targets for non-fission neutron production.

Low melting temperature alloy Ingredient

|

No |

Composition(wt.%) |

Melting zone temperature /℃ |

Purity |

Tips |

|||||

|

Bi |

Pb |

Sn |

Cd |

Start |

Finish |

Self weight flow point |

(%) | ||

|

1 |

50.0 |

26.7 |

13.3 |

10.0 |

70 |

70 |

70 |

eutectic |

|

|

2 |

52.0 |

32.0 |

16.0 |

- |

95 |

95 |

95 |

eutectic |

|

|

3 |

54.4 |

43.6 |

1.0 |

1.0 |

104 |

115 |

112 |

Non- eutectic |

|

|

4 |

55.5 |

44.5 |

- |

- |

- |

- |

- |

99.995 |

|

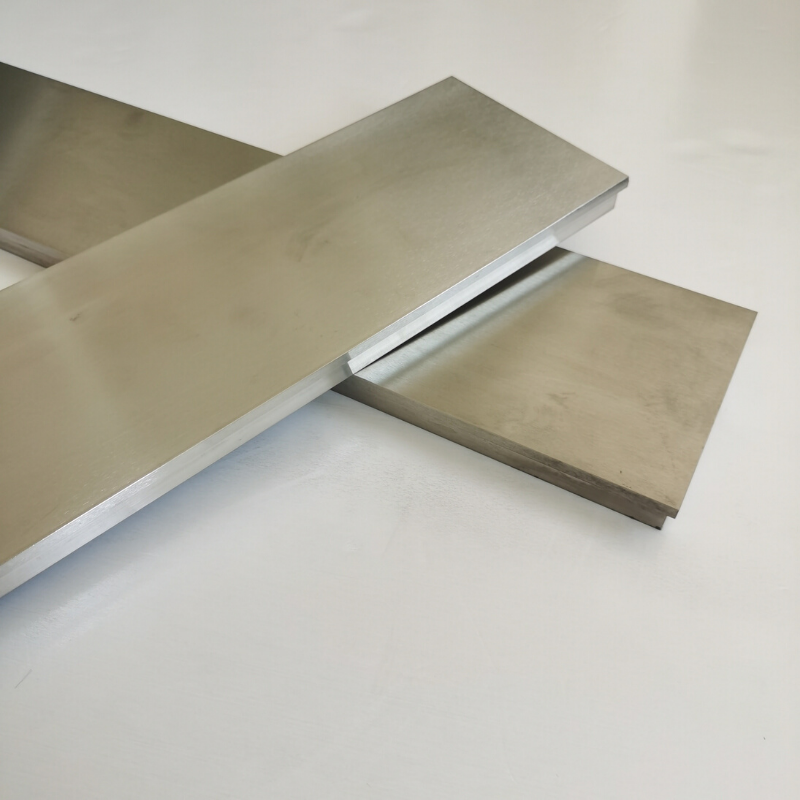

Lead Bismuth Sputtering Target Packaging

Our Lead Bismuth sputter target is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

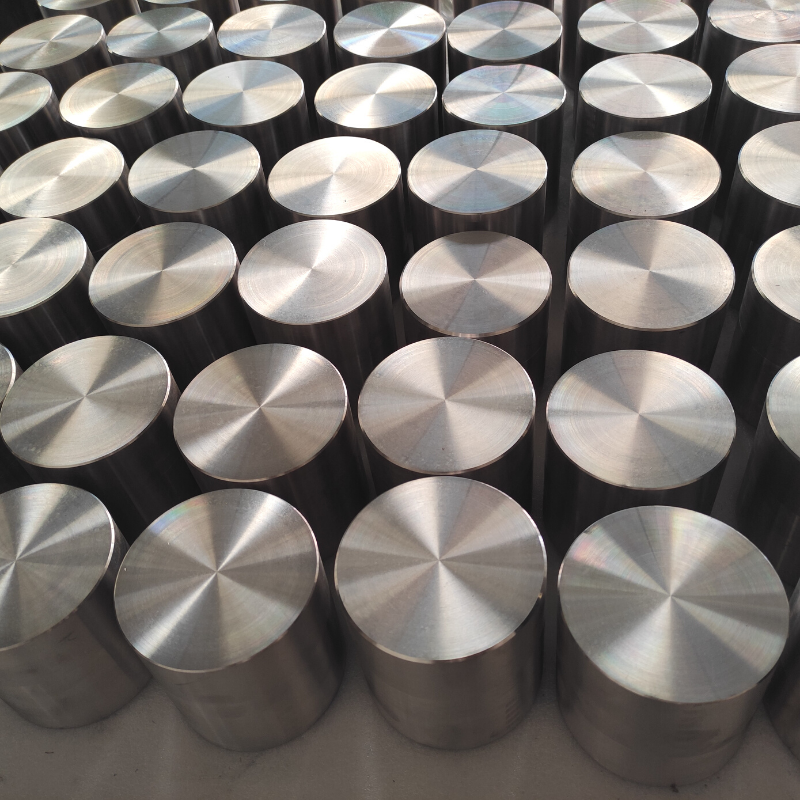

Get Contact

RSM’s Lead Bismuth sputtering targets are of ultra-high purity and uniform. They are available in various forms, purities, sizes, and prices. We specialize in producing high purity thin film coating materials with excellent performance as well as the highest possible density and smallest possible average grain sizes for use in mold coating、decoration、automobile parts、low-E glass、semi-conductor integrated circuit、thin film resistance、graphic display、aerospace、 magnetic recording、touch screen、thin film solar battery and other physical vapor deposition (PVD) applications. Please send us an inquiry for current pricing on sputtering targets and other deposition materials not listed.

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Newly Arrival Electron-Beam Melting - Pbbi Alloy Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich , The product will supply to all over the world, such as: Stuttgart, Puerto Rico, Mecca, With the intensified strength and more reliable credit, we are here to serve our customers by providing the highest quality and service, and we sincerely appreciate your support. We will endeavor to maintain our great reputation as the best products supplier in the world. If you have any questions or comments, please contact with us freely.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.